Looking for a heavy-duty Pneumatic Busbar Marking Machine? Our Integrated Dot Peen System delivers deep, permanent Pin Marking on Copper & Aluminium busbars. Ideal for Switchgear & Panel Builders requiring clear Phase & Neutral identification even after painting. Compatible with CNC Busbar Processing Lines. Contact us today for the best price in India and upgrade your busbar fabrication efficiency.

Automatic Pneumatic Busbar Marking Machine (Dot Peen) for Indian Panel Builders

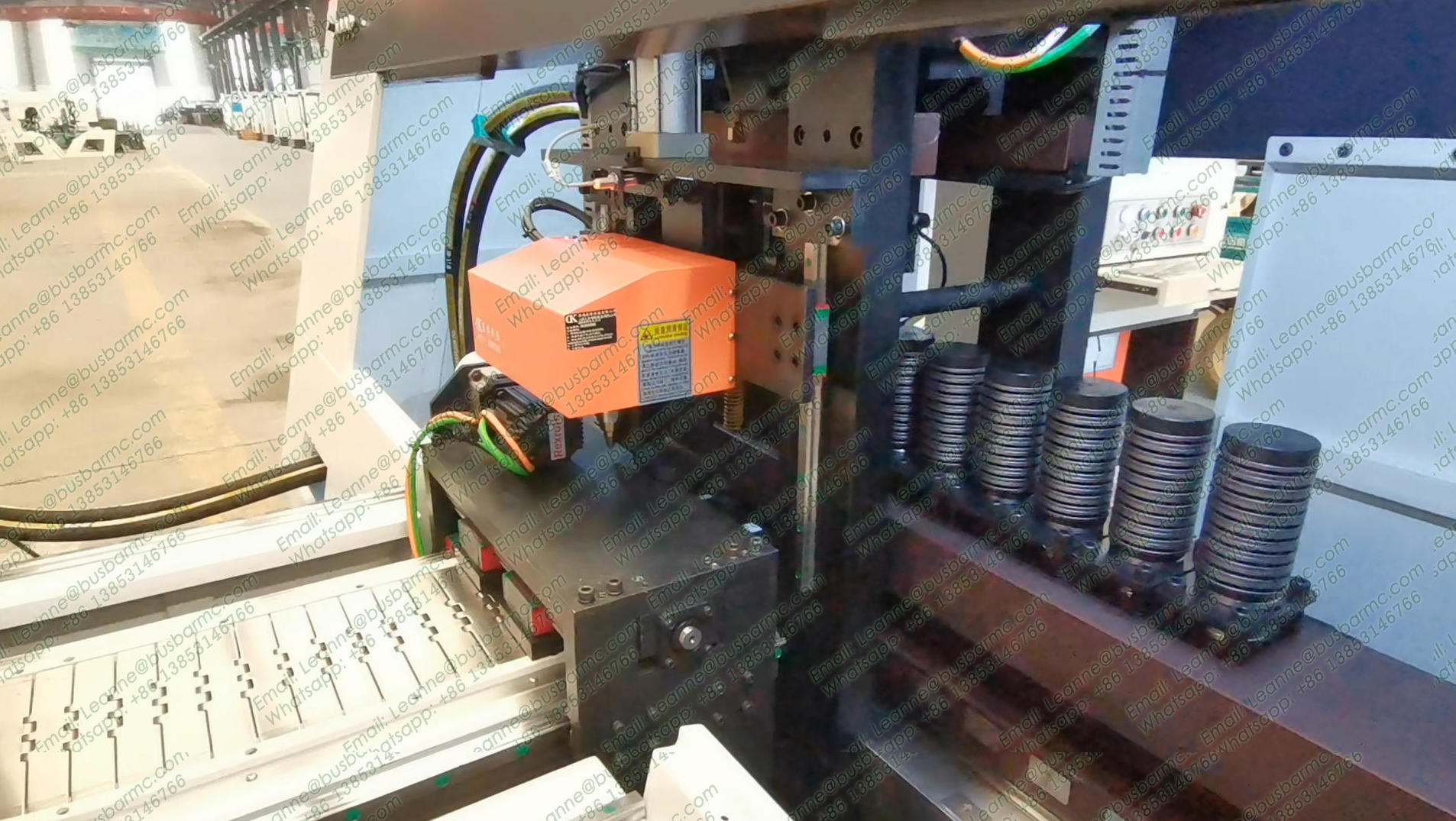

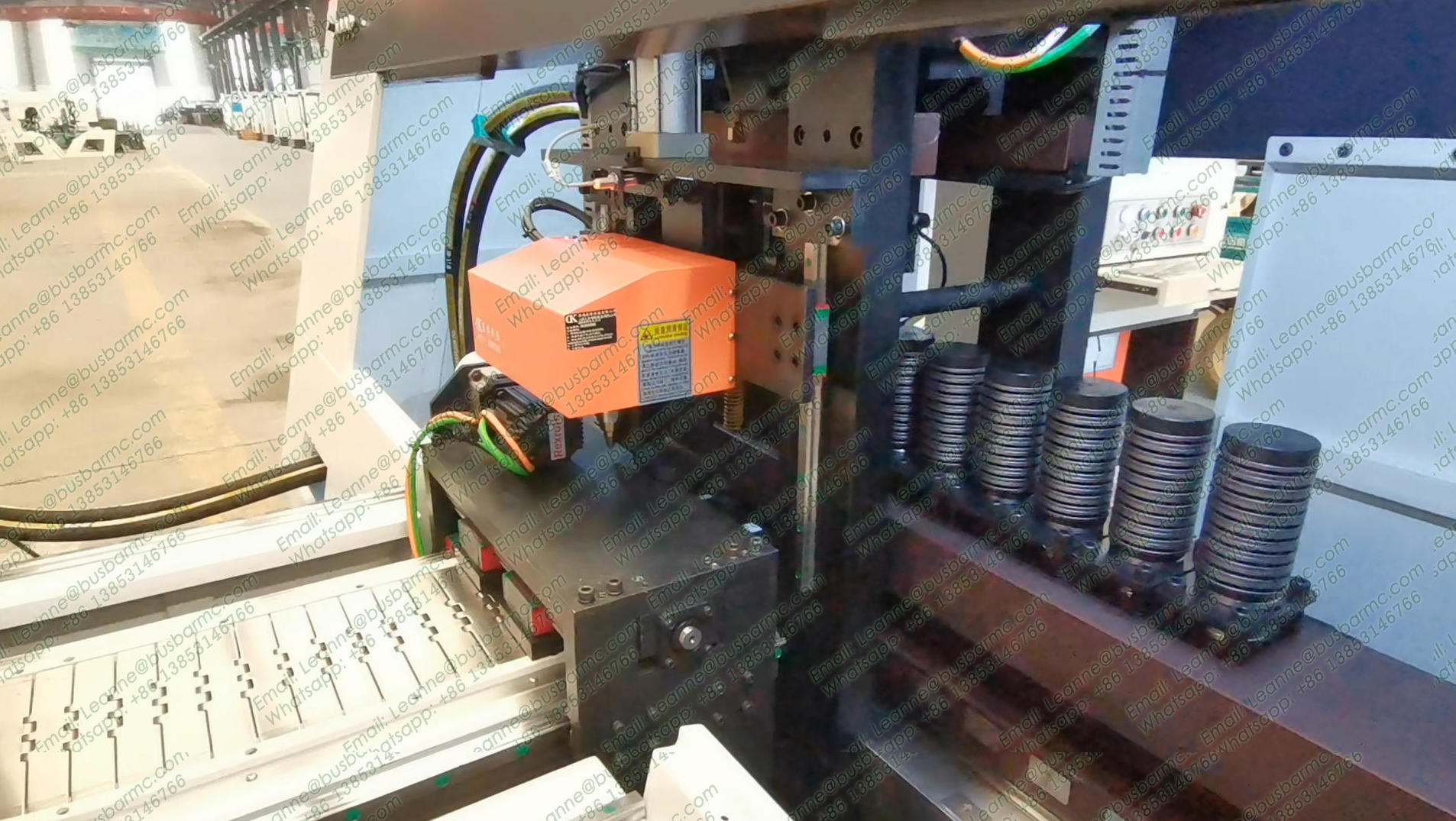

Upgrade your facility with our Pneumatic Marking Machine integrated with Busbar Processing Machine. This system is engineered to achieve fast, clear, and Deep Pin Marking on copper and aluminium busbars, ensuring visibility even after painting or coating.

It is the ideal solution for Indian Switchgear factories that need automatic marking during busbar punching, bending, cutting, and assembly processes.

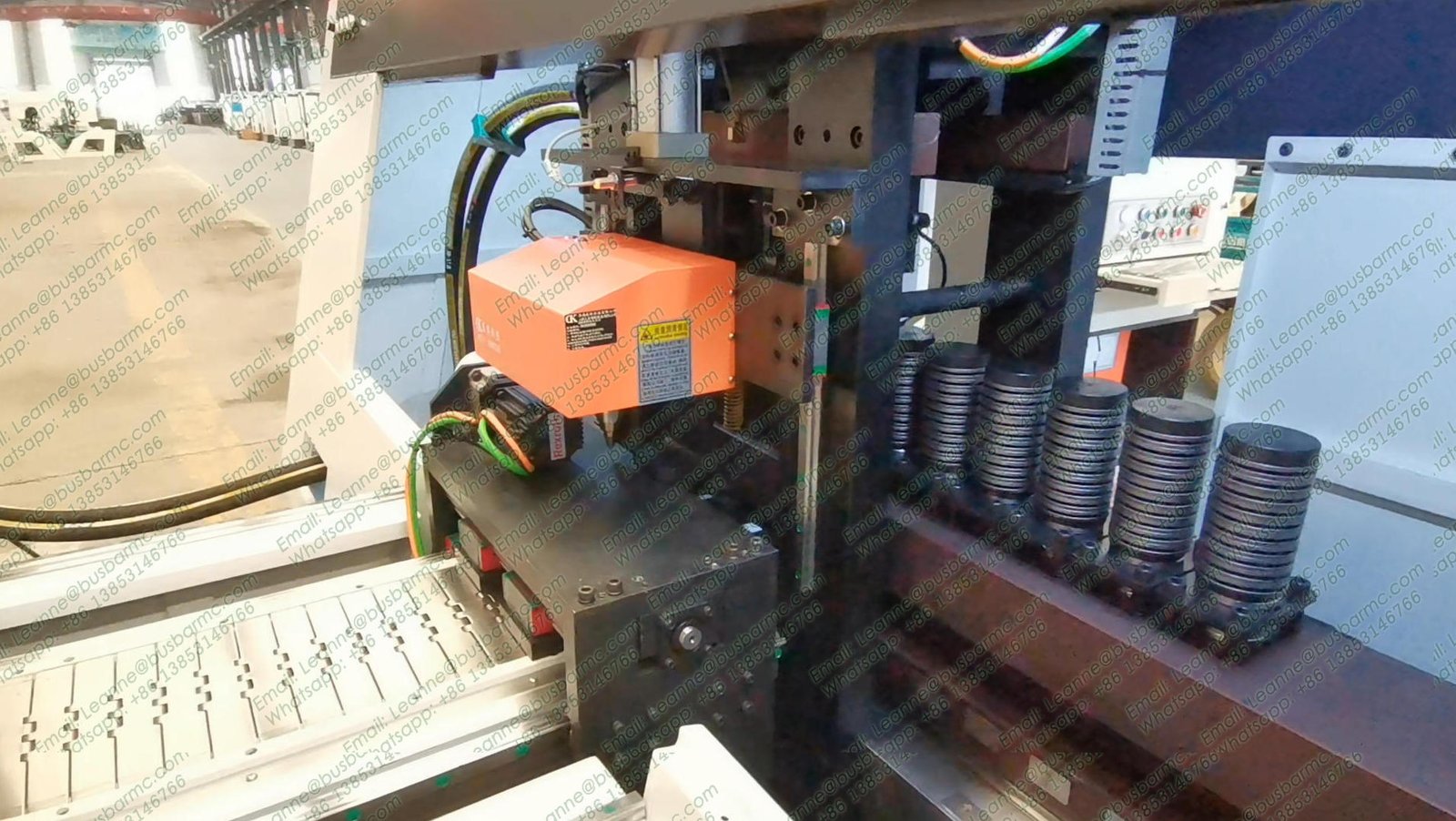

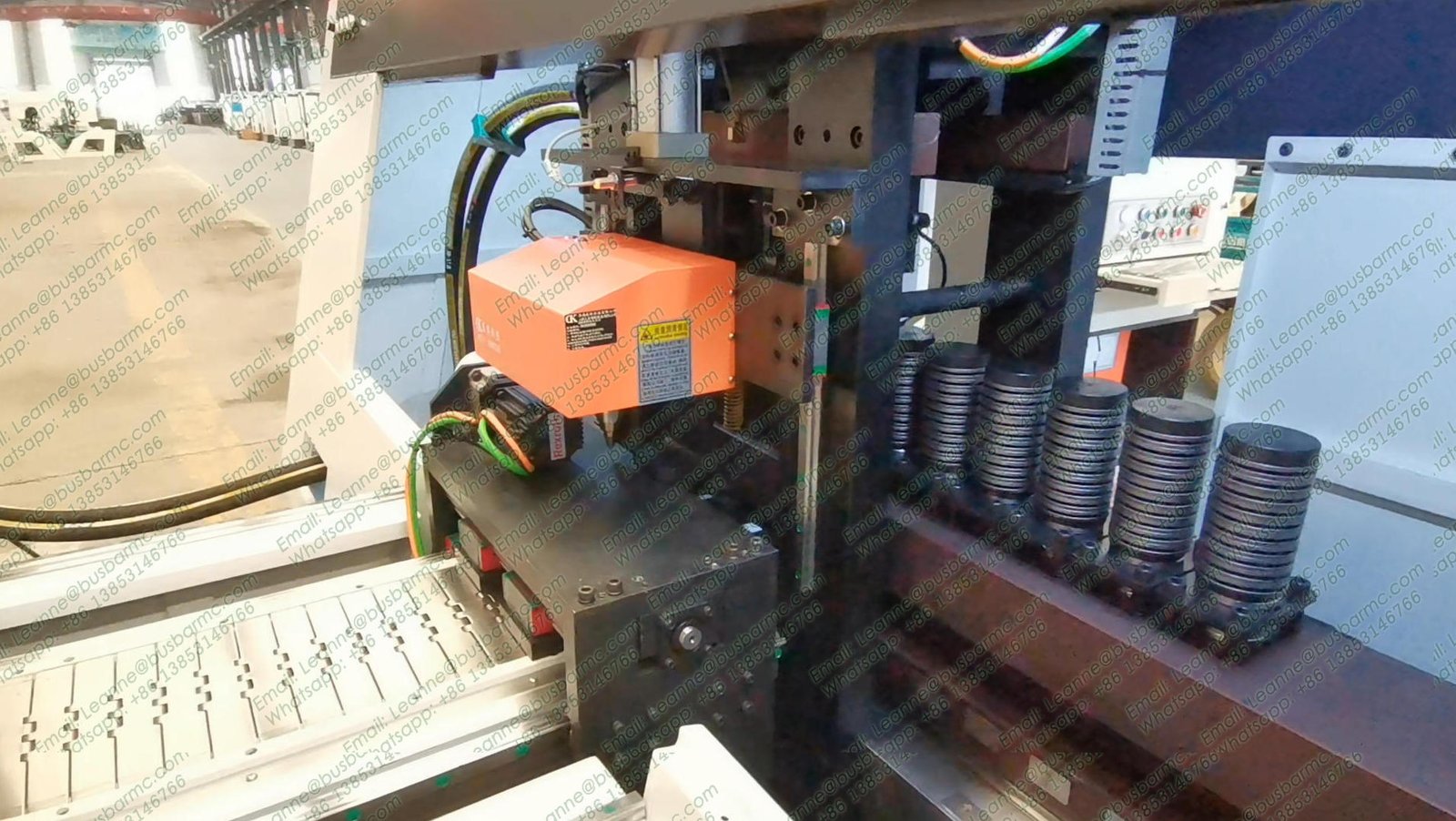

Integrated Dot Peen Pneumatic Marking System designed for heavy-duty busbar production lines.

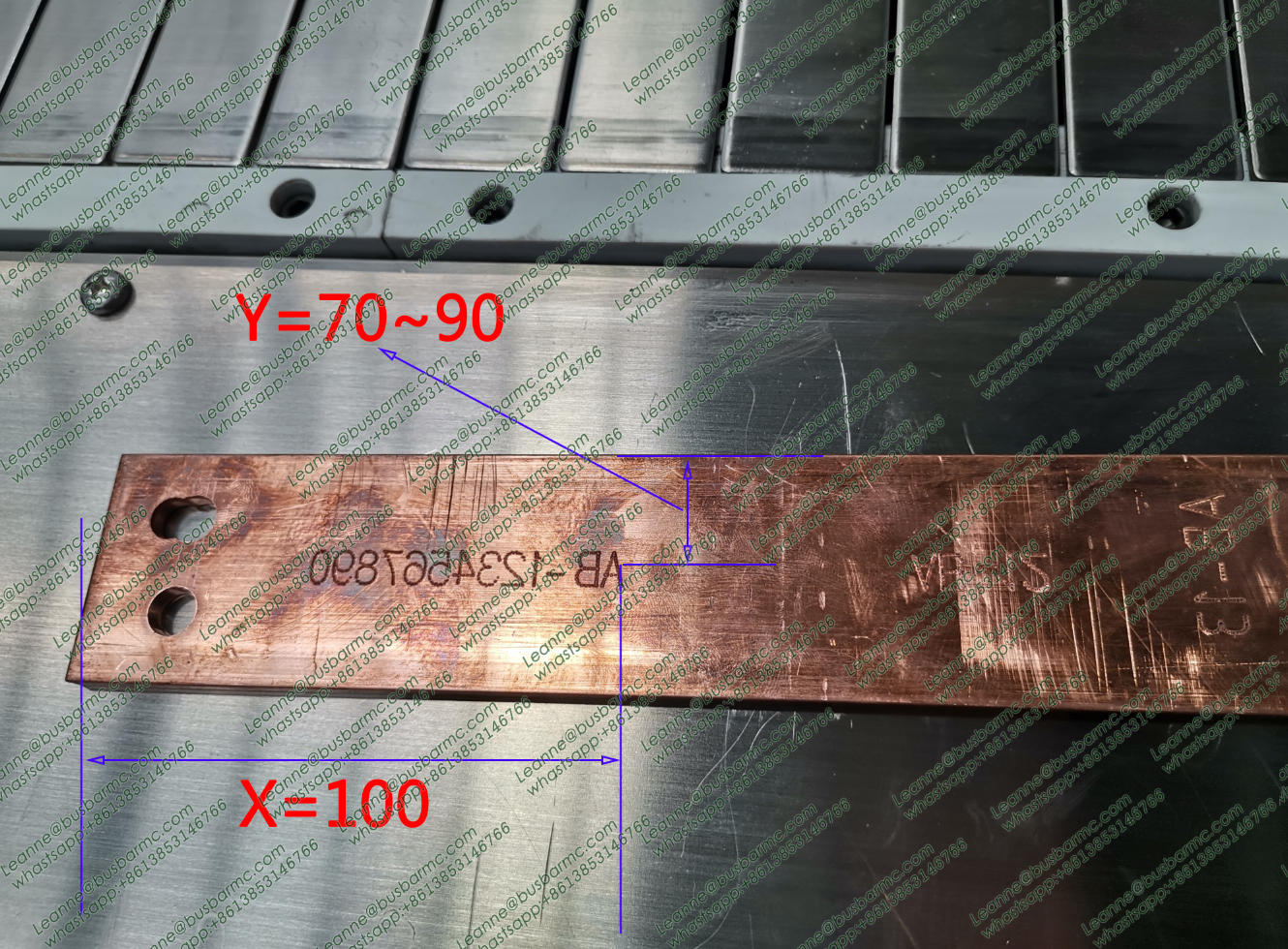

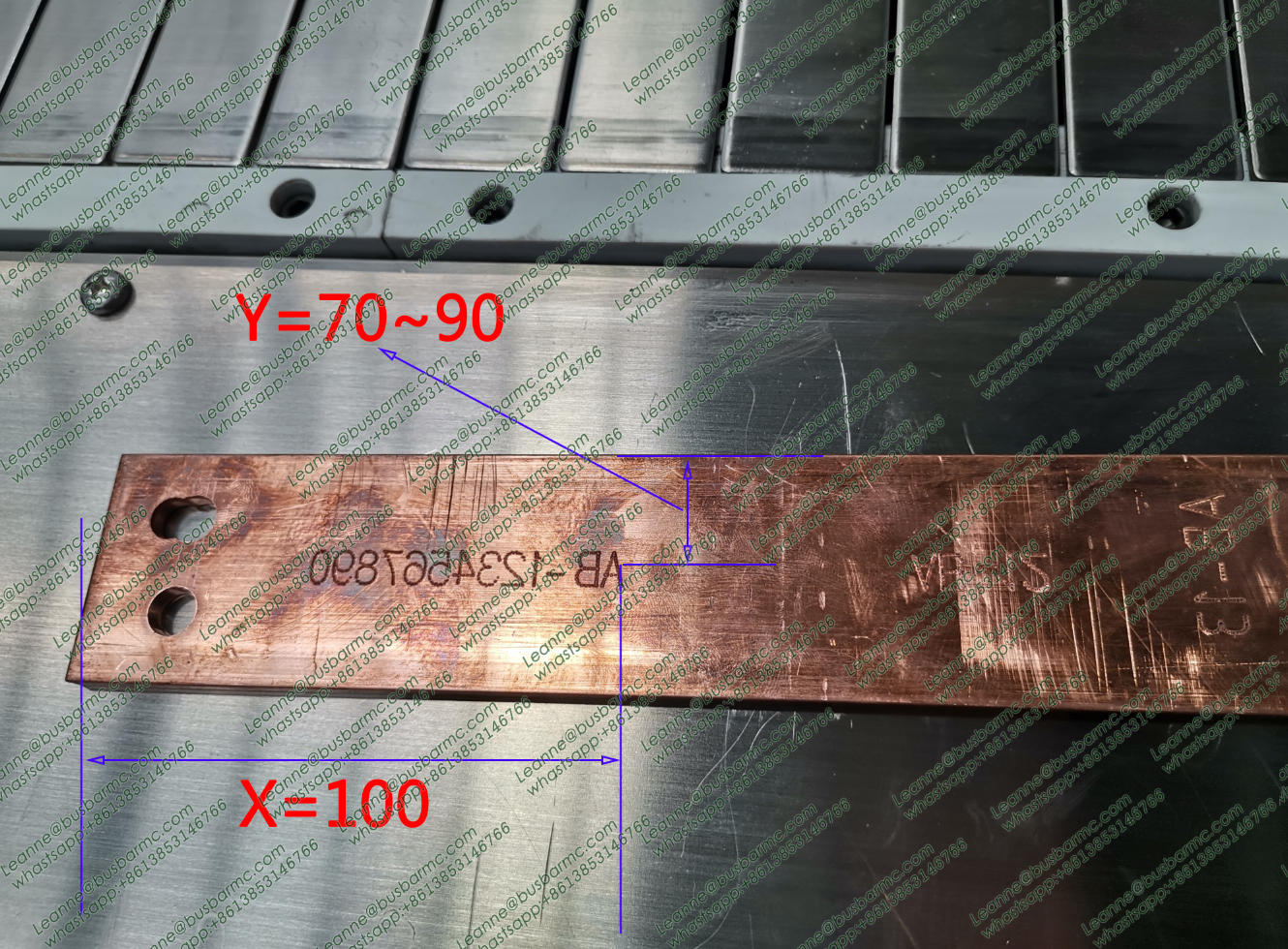

Suitable for both Copper & Aluminium busbars (5–15 mm thickness), handling standard Indian busbar sizes.

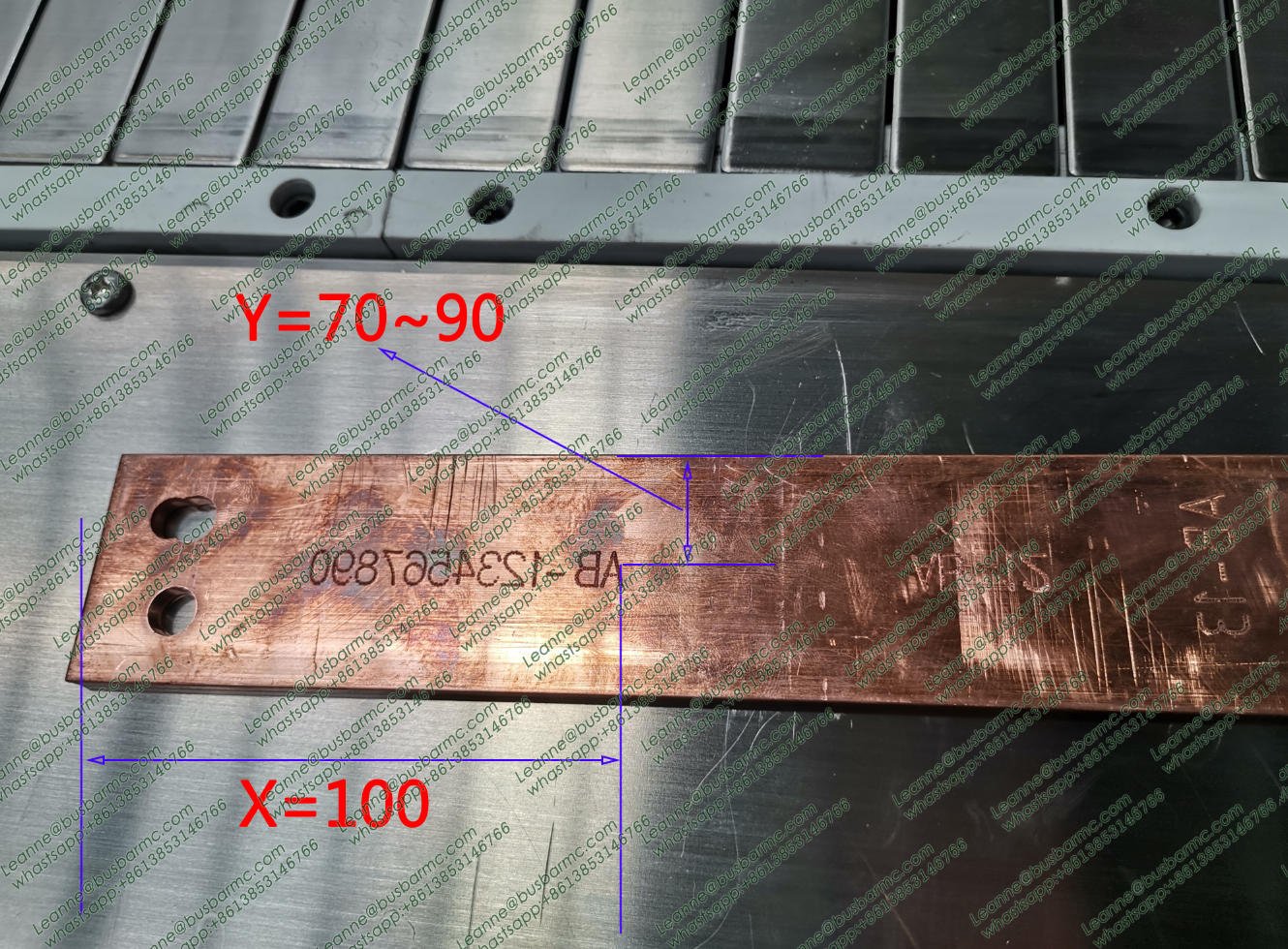

Precision marking of Phase Details (R-Y-B), Serial Numbers, Batch Codes, and Company Logos.

High marking speed with Deep Engraving Capability – marks remain visible after powder coating.

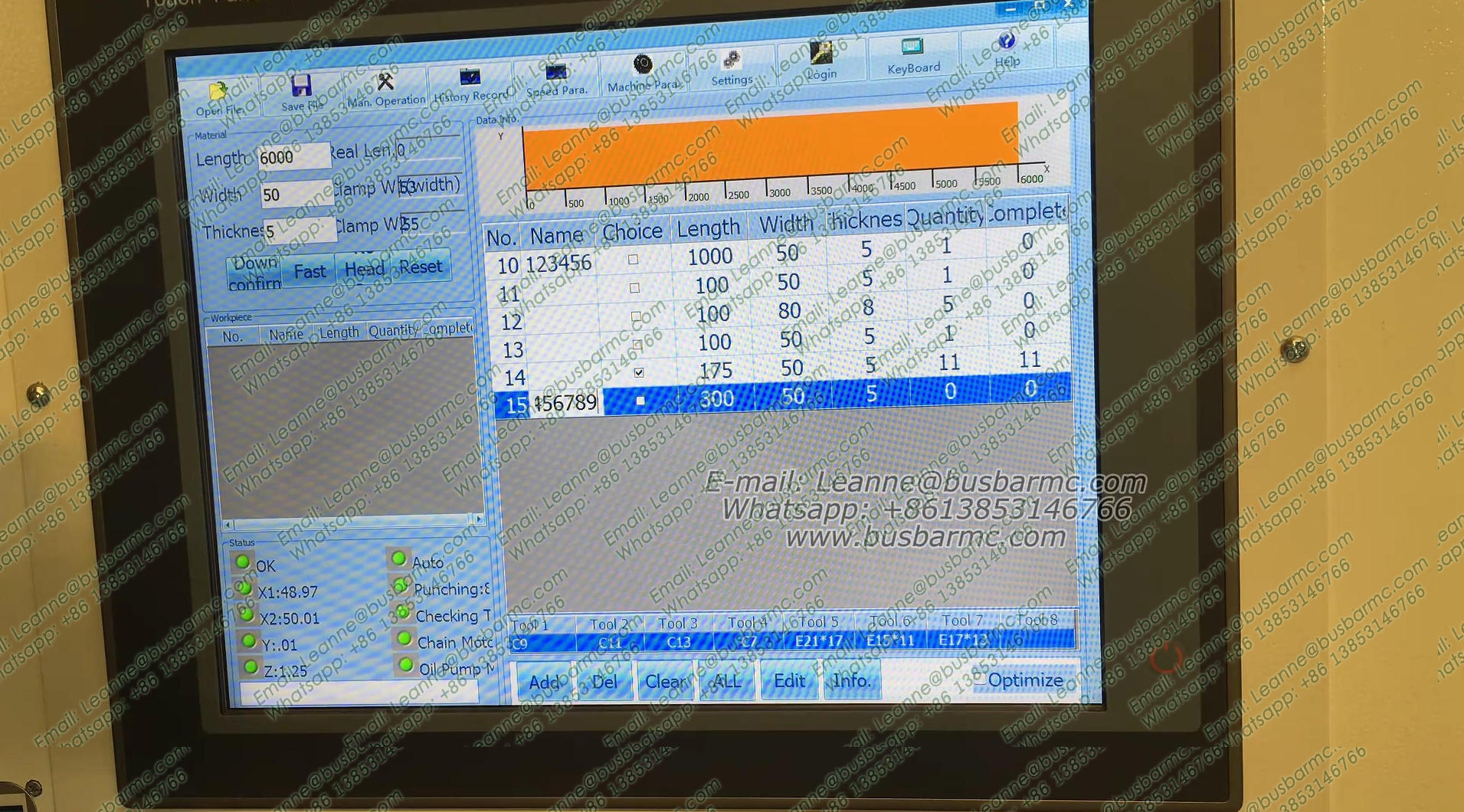

Fully compatible with CNC busbar fabrication machines and automated punching centers.

Rugged stable structure, low maintenance, and long service life for Indian industrial conditions.

Busbar fabrication workshops & Processing Centers.

Electrical Switchgear Manufacturing (LT/HT Panels).

Power distribution cabinet production (PCC & MCC Panels).

Substation equipment & Transformer component factories.

This integrated pneumatic marking device is perfect for improving workflow efficiency and product traceability in busbar production lines across India.

Busbar Machine Pneumatic Marking Demo Video:

Industry Tags:

Pneumatic marking machine India, Dot peen marking system for busbar, Busbar pin marking machine, Copper busbar embossing tool, Automatic busbar coding machine, Aluminium busbar identification, Heavy duty busbar marking, Switchgear panel marking system, Busbar punching marking integration, CNC busbar machine with marker.

| Item | Specification |

| Marking Method | Pneumatic Dot Peen Marking (Pin Marking) |

| Applicable Materials | Copper Busbar, Aluminium Busbar, Metal Plates |

| Busbar Thickness | 5 – 15 mm |

| Marking Depth | 0.01 – 1.0 mm Adjustable (Deep Marking) |

| Marking Speed | Up to 5 Characters / Second |

| Marking Content | Text, Serial Numbers, Dates, Batch Codes, Simple Logos |

| Air Pressure | 0.2 – 0.6 MPa |

| Power Supply | AC 110V / 220V, 50/60Hz |

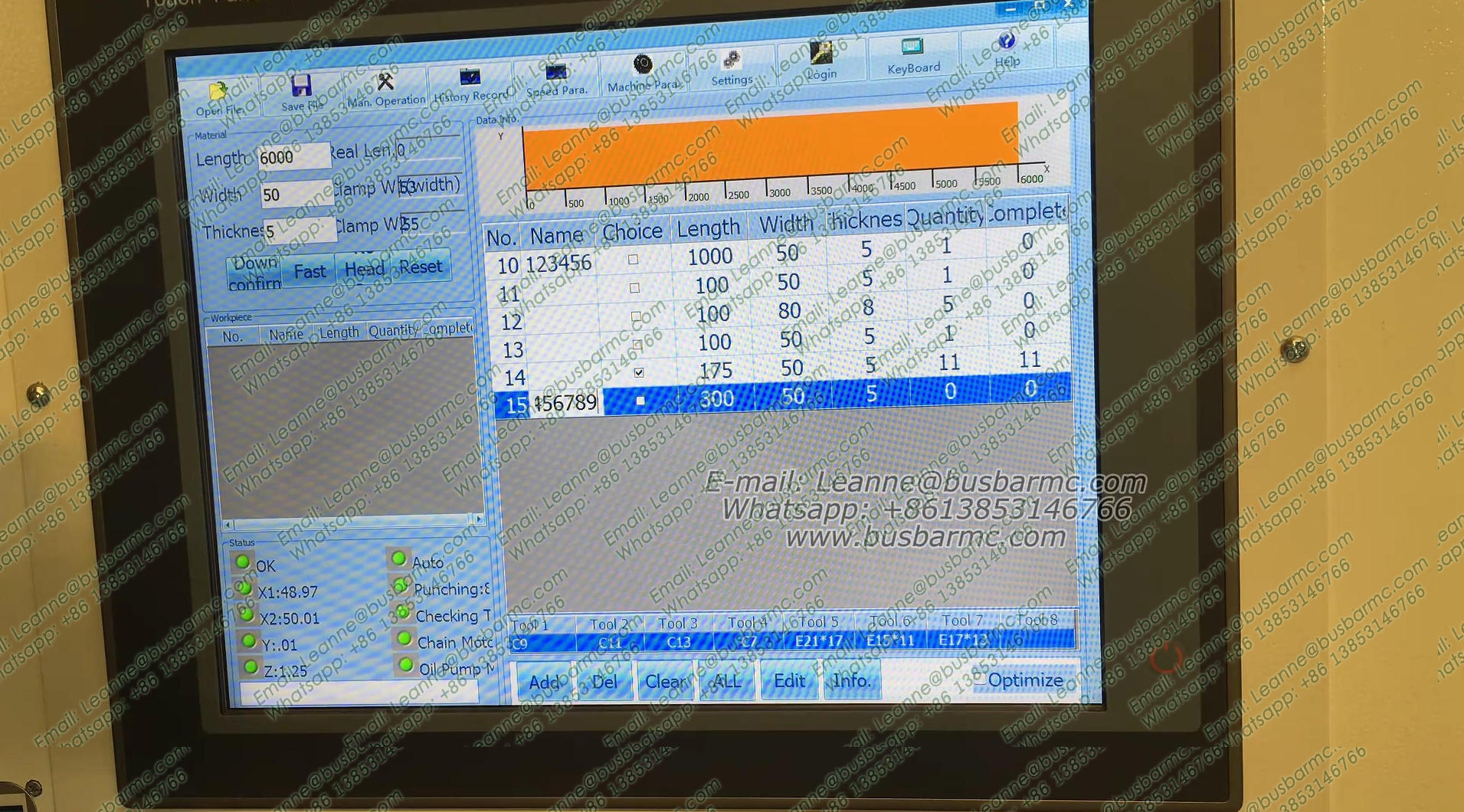

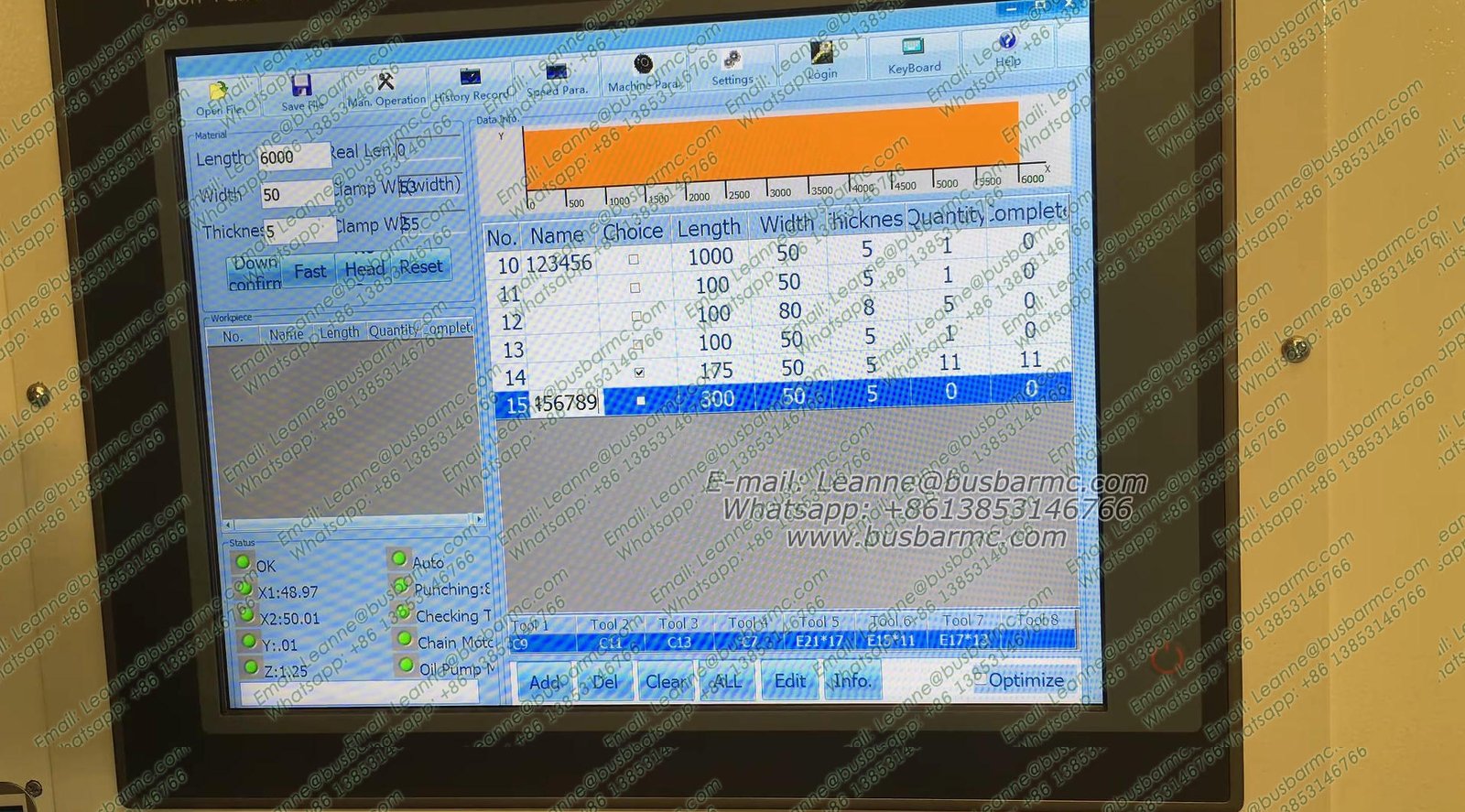

| Control System | Industrial Controller / CNC Interface |

| Integration Type | Integrated with Busbar Punching, Bending and Cutting Machine |

| Operating Mode | Automatic Online Marking |

| Service Life | ≥ 100,000 Hours |

Q1: Will the marking remain visible after painting or powder coating?

Yes. Unlike laser marking, our Pneumatic Dot Peen system provides Deep Pin Marking (up to 1.0mm). This ensures the characters remain legible on copper and aluminium busbars even after powder coating or sleeving.

Q2: Can this machine be integrated into my existing Busbar Production Line?

Yes. It is designed for seamless integration with CNC Busbar Punching, Bending, and Cutting machines for automatic inline operation.

Q3: Is it suitable for Indian electrical standards?

Absolutely. The machine works on standard AC 220V power and handles standard busbar thicknesses (5-15mm) used in LT/HT panels.

Q4: What maintenance does the marking head require?

The system is low maintenance. You mainly need to ensure a clean air supply and occasionally replace the marking pin (stylus) after long-term heavy usage.

Q5: Can it mark logos and special codes?

Yes. The software supports alphanumeric text, dates, batch codes, serial numbers, and simple company logos for branding your switchgear components.

Q6: Does it work on Aluminium Busbars?

Yes, it provides excellent results on both Copper and Aluminium busbars without deforming the material.

Pneumatic Busbar Marking Machine India, Dot Peen Marking for Copper Busbar, Busbar Identification System, Deep Marking Machine for Switchgear, Automatic Busbar Coding Tool

Pneumatic marking machine price in India, busbar dot peen marker, pin marking machine for aluminium busbar, copper busbar embossing machine, busbar punching and marking machine, integrated busbar marking system, heavy duty pneumatic marker, dot peen engraving machine for metal, busbar fabrication machine spare parts, marking machine for electrical panel builders, automatic numbering machine for busbars, pneumatic indent marking machine, deep pin marking system, busbar production line equipment, switchgear manufacturing machines India, CNC busbar machine with marking unit, R Y B phase marking tool, busbar tagging machine.