Looking for a high-precision HQ400-2000B Servo CNC Busbar Bending Machine in India? Our fully Automatic Hydraulic Busbar Bender is designed for heavy-duty Copper and Aluminium busbars. Ideal for Electrical Control Panel and Switchgear manufacturers requiring accurate bending angles (Z-bend, U-bend, L-bend). Features Siemens/Panasonic PLC control for mass production. Contact us for the best CNC busbar bending machine price in India and upgrade your fabrication workshop.

HQ400-2000B Servo CNC Copper & Aluminium Busbar Bending Machine (India)

Description:

The LT HQ400-2000B is a high-performance Servo CNC Hydraulic Busbar Bending Machine designed for the Indian power industry. It is engineered for precise bending of heavy-duty Copper and Aluminium busbars (Copper Patti & Aluminium Flats).

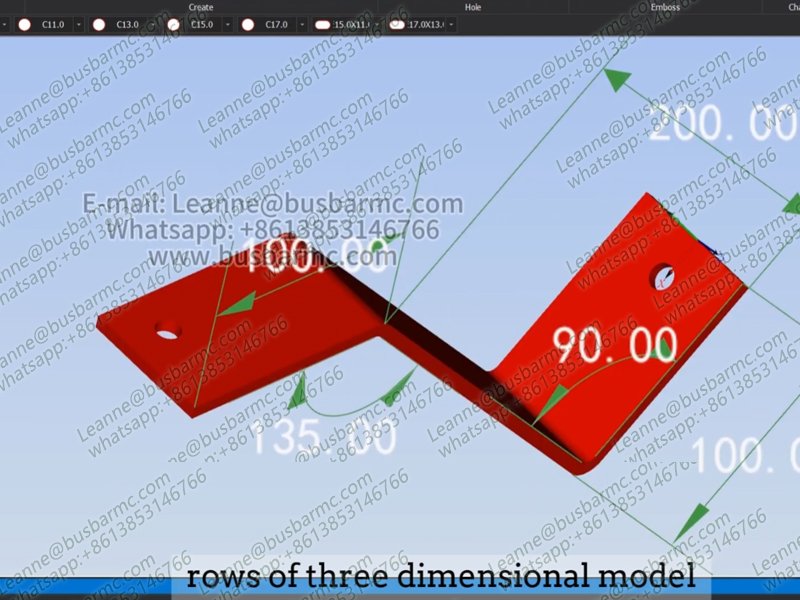

Adopting an advanced CNC numerical control system with Servo Motors and specialized CAD/CAM software, this machine ensures exceptional automation and high efficiency. It is the ideal solution for manufacturing High/Low Voltage Switchgear, Control Panels, and Transformers in India.

The busbar bending process features high precision (±0.3°) and superior repeatability, thanks to its robust closed bending structure and servo-driven system.

Contact us now for the latest CNC Busbar Bending Machine Price in India and detailed technical specifications.

CNC Servo Busbar Bending Machine Demo Video:

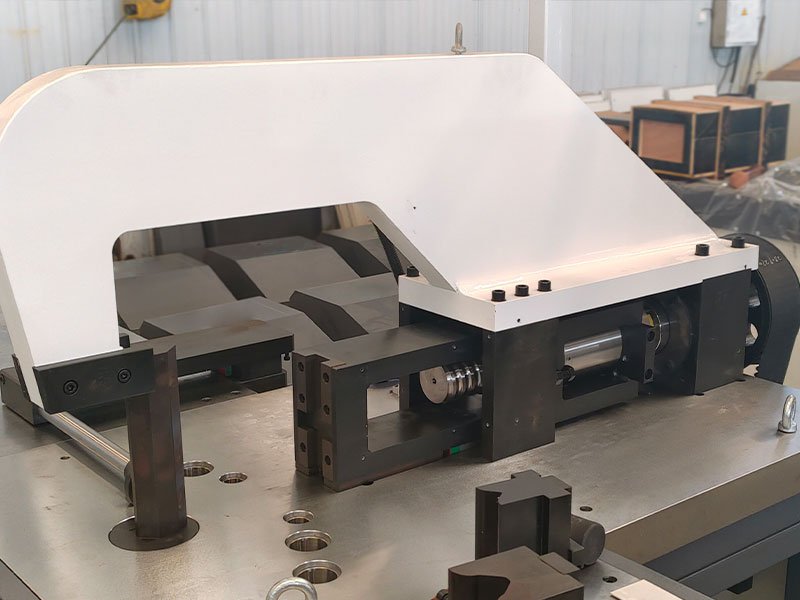

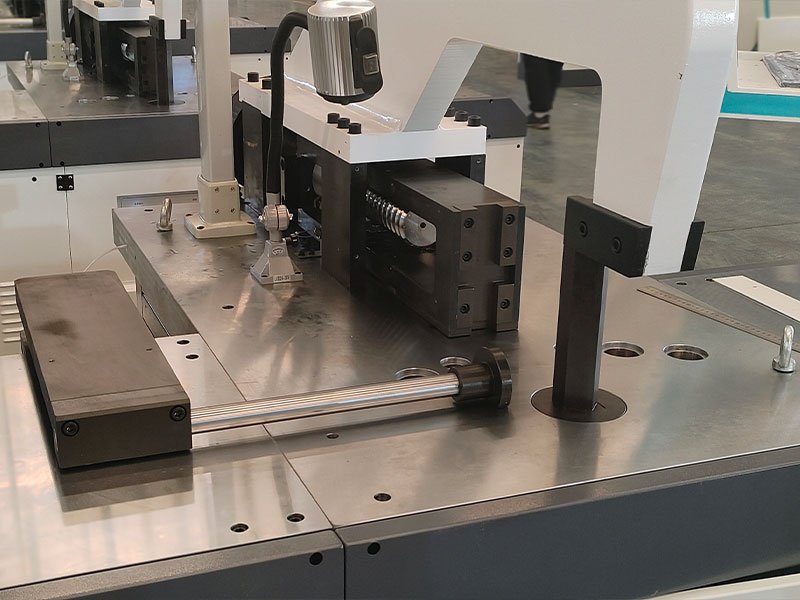

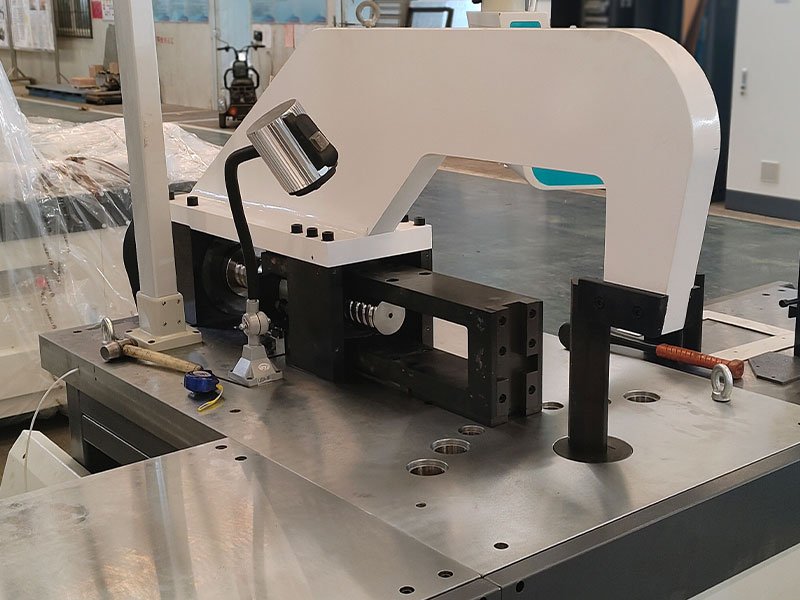

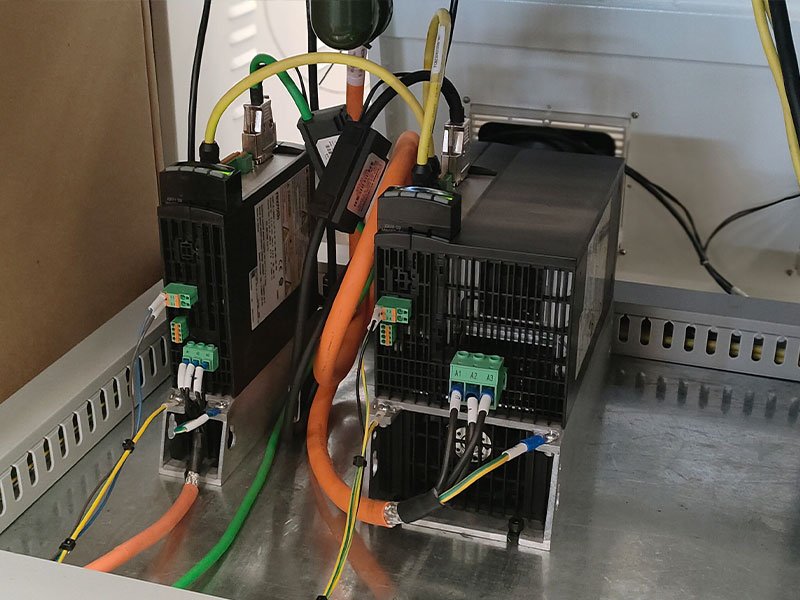

Machine Details & Factory View:

Key Features:

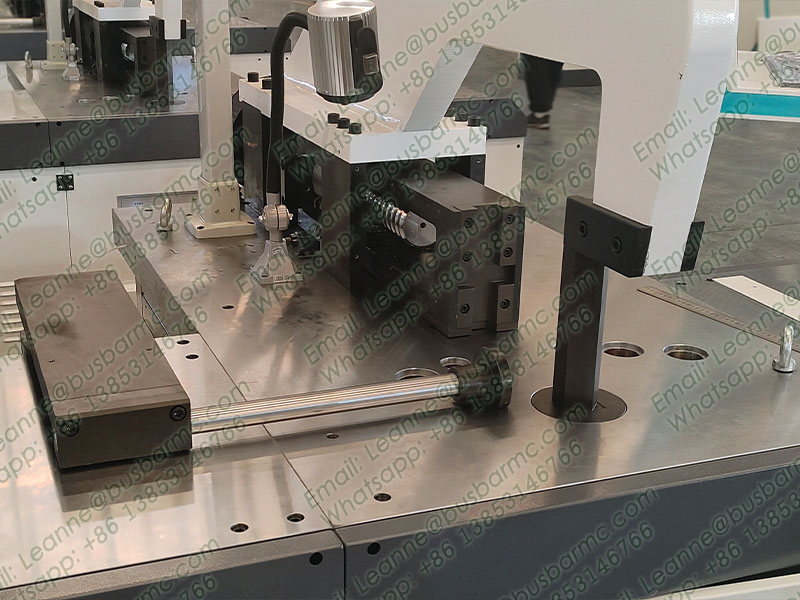

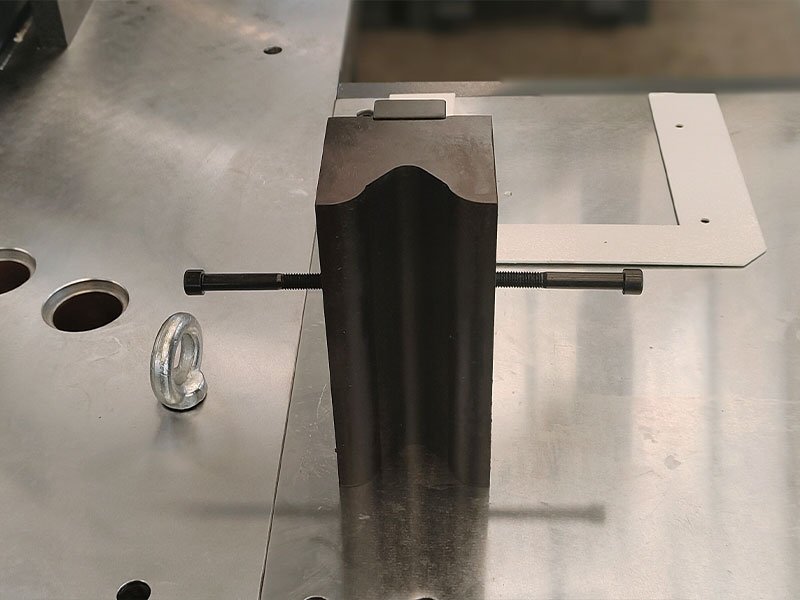

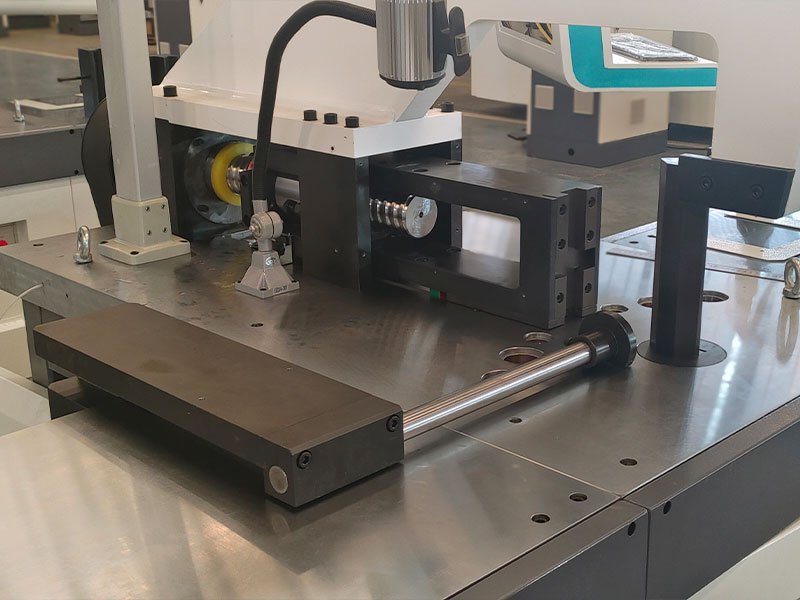

1. Closed Bending Structure:

The unique closed frame design ensures uniform force distribution and significantly enhances mechanical strength compared to open bending systems. This guarantees consistent angles for heavy copper bars.

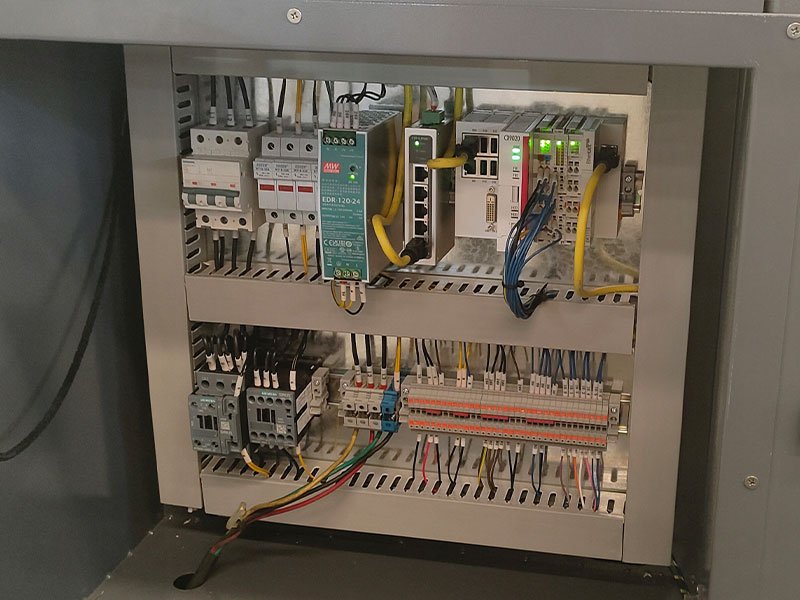

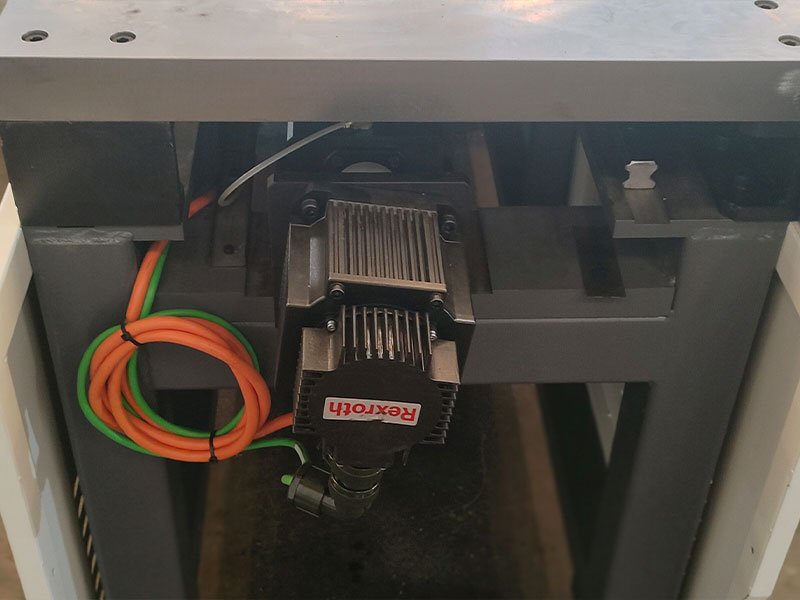

2. Servo Motor Power System:

Driven by high-precision Servo Motors, the transmission is stable and unaffected by temperature changes, ensuring superior repeat positioning accuracy (±0.02mm).

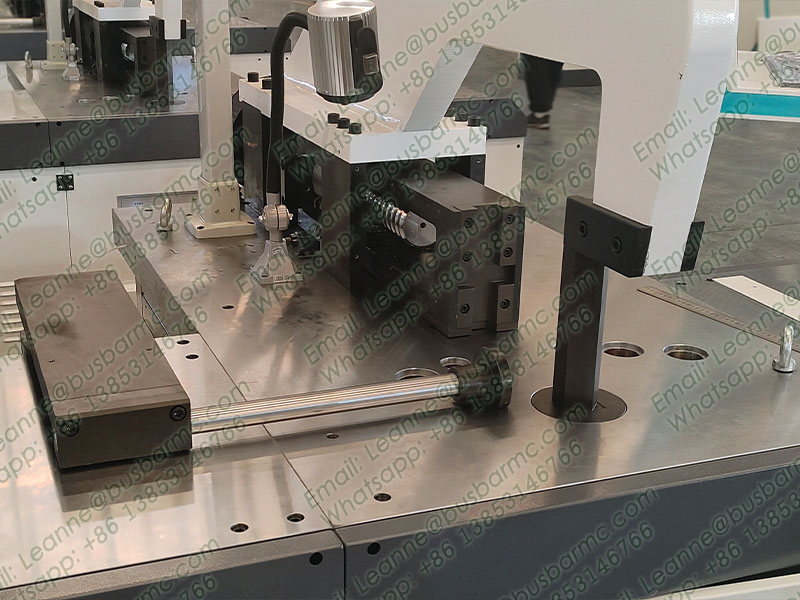

3. CNC Stopper (Backgauge):

The modular CNC stopper design allows for customized lengths and smooth, automated operation for mass production.

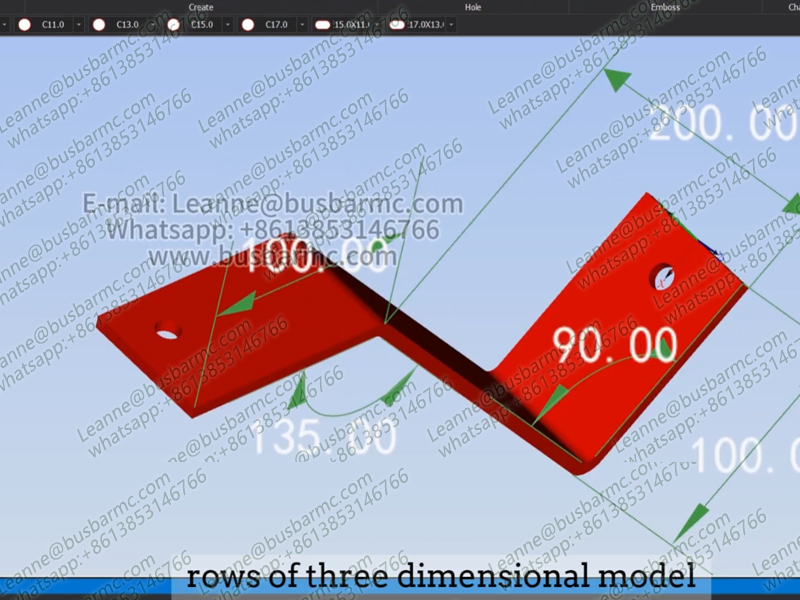

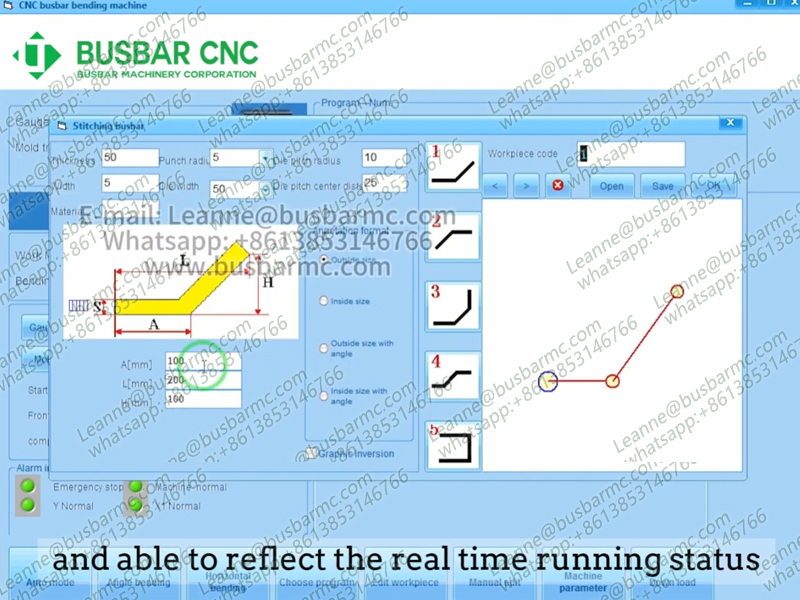

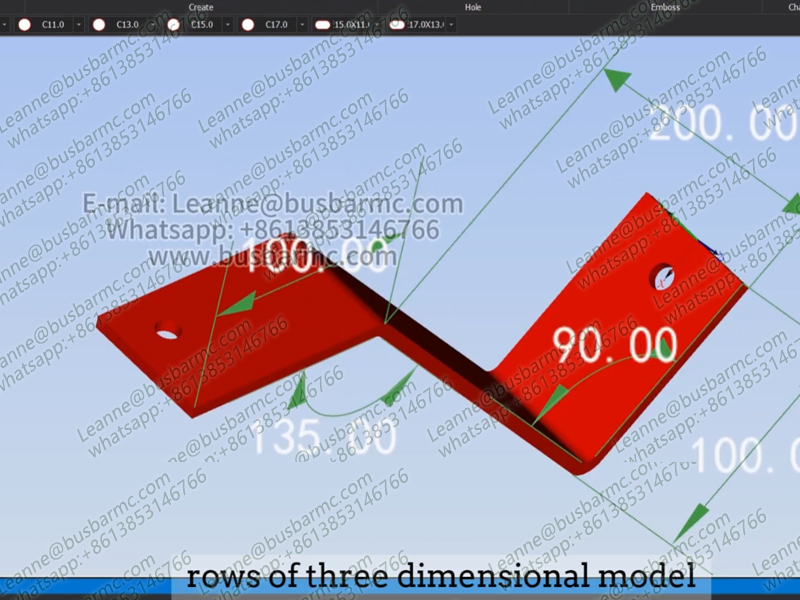

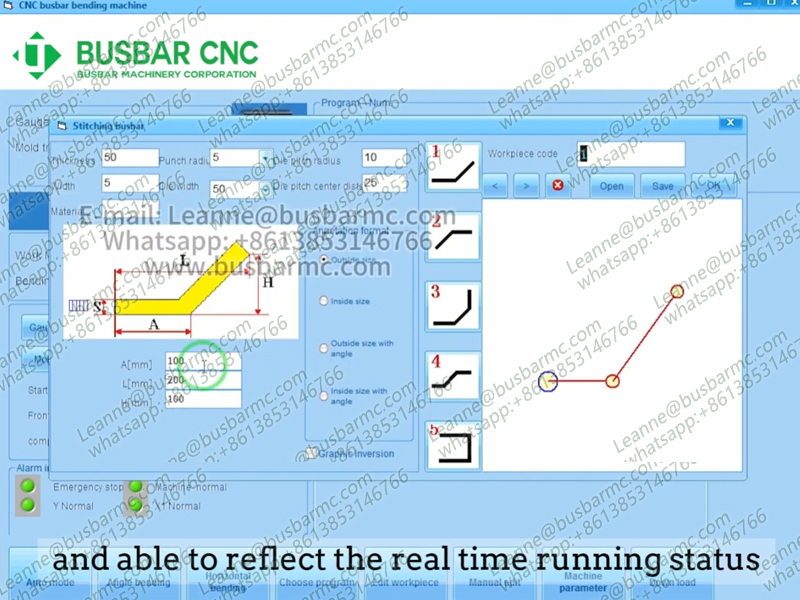

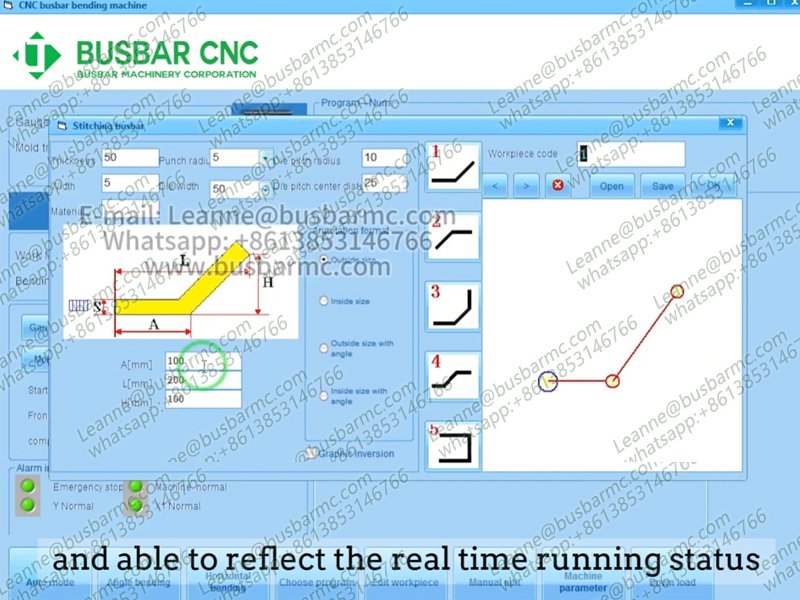

4. CNC Control + CAD/CAM Software:

Equipped with an intuitive Touch Screen CNC unit and specialized CAD/CAM software. It automatically calculates the unfolding length, making it ideal for High/Low Voltage Panels, Box-type Substations, and Busduct systems.

Technical Specifications – HQ400-2000B:

| Model | HQ400-2000B |

| Nominal Pressure | 400KN |

| Hydraulic Cylinder Stroke | 250mm |

| Main Motor Power | 5.5kw |

| Gauge Length | 2000mm |

| Gauge Accuracy | +/-0.15mm |

| Bending Accuracy | +/-0.3° |

| Bending Head Speed (Y Axis) | Fastest 5m/min; Low: 1.25m/min |

| Max Moving Speed of Side Striker (X Axis) | 15m/min |

| Y-axis Repeat Positioning Accuracy | +/-0.02mm |

| Horizontal Bending Max. Size | 15mm x 160mm |

| Vertical Bending Max. Size | 12mm x 120mm |

| Y-axis Servo Motor Power | 5.5kw |

| X-axis Servo Motor Power | 0.75kw |

| Machine Weight | 3300kg |

| Overall Dimensions | 4300mm x 1450mm x 1850mm |

1. What materials can this CNC Busbar Bending Machine process?

A: It is designed for high-precision bending of Copper and Aluminium busbars (Copper Patti & Aluminium Flats) widely used in Indian electrical panels.

2. What is the bending capacity (Size)?

A: It can handle a maximum size of 15mm × 160mm for Horizontal Bending and 12mm × 120mm for Vertical Bending.

3. How accurate is the bending angle?

A: Thanks to the Servo Motor control and closed structure, it offers a high bending accuracy of ±0.3° and repeat positioning accuracy of ±0.02mm.

4. What power supply is required?

A: It uses a 5.5kW main motor plus servo motors. We can customize the voltage (e.g., 415V, 50Hz, 3-Phase) to match Indian industrial standards.

5. Does it come with software?

A: Yes, it includes a dedicated CAD/CAM system that automatically calculates the spring-back and unfolding length of the busbar, simplifying the programming process.

6. What industries use this machine?

A: It is widely used by manufacturers of High/Low Voltage Switchgear, Electrical Control Panels (PCC/MCC), Transformers, and Busducts.

7. How do I get the price in India?

A: Please contact our sales team via WhatsApp or Email. We provide competitive CNC Busbar Machine Prices in India with full technical support.

Servo CNC Busbar Machine India, Automatic Copper Busbar Bender, Aluminium Busbar Bending Machine Price, Hydraulic Busbar Press Brake, Heavy Duty Busbar Machine Manufacturer

Industry Keywords: HQ400-2000B busbar machine, servo CNC copper busbar bending machine, automatic busbar bending machine India, CNC busbar processing equipment, copper aluminium busbar bending system, programmable busbar bending machine, hydraulic copper busbar bending machine, servo motor busbar bending machine, industrial copper busbar bender, precision CNC busbar bending machine, busbar forming and bending machine, CAD/CAM busbar bending equipment, electrical switchgear busbar bending machine, transformer manufacturing busbar bender, closed-structure busbar bending machine, CNC horizontal vertical busbar bending machine, copper bar bending equipment, electric control panel busbar bender, customized busbar bending machine, power distribution busbar processing equipment.