Discover the HQ600-S-8P High Speed CNC Busbar Punching Machine, designed for precision fabrication in India. This heavy-duty Servo-driven system features an 8-station turret for continuous punching of Copper and Aluminium busbars (Copper Patti). Ideal for Switchgear, Electrical Panel, and Transformer manufacturers. Enhance your production speed with high accuracy and low maintenance. Contact us today for the best CNC busbar machine price in India and technical specifications.

HQ600-S-8P High Speed CNC Busbar Punching Machine (India)

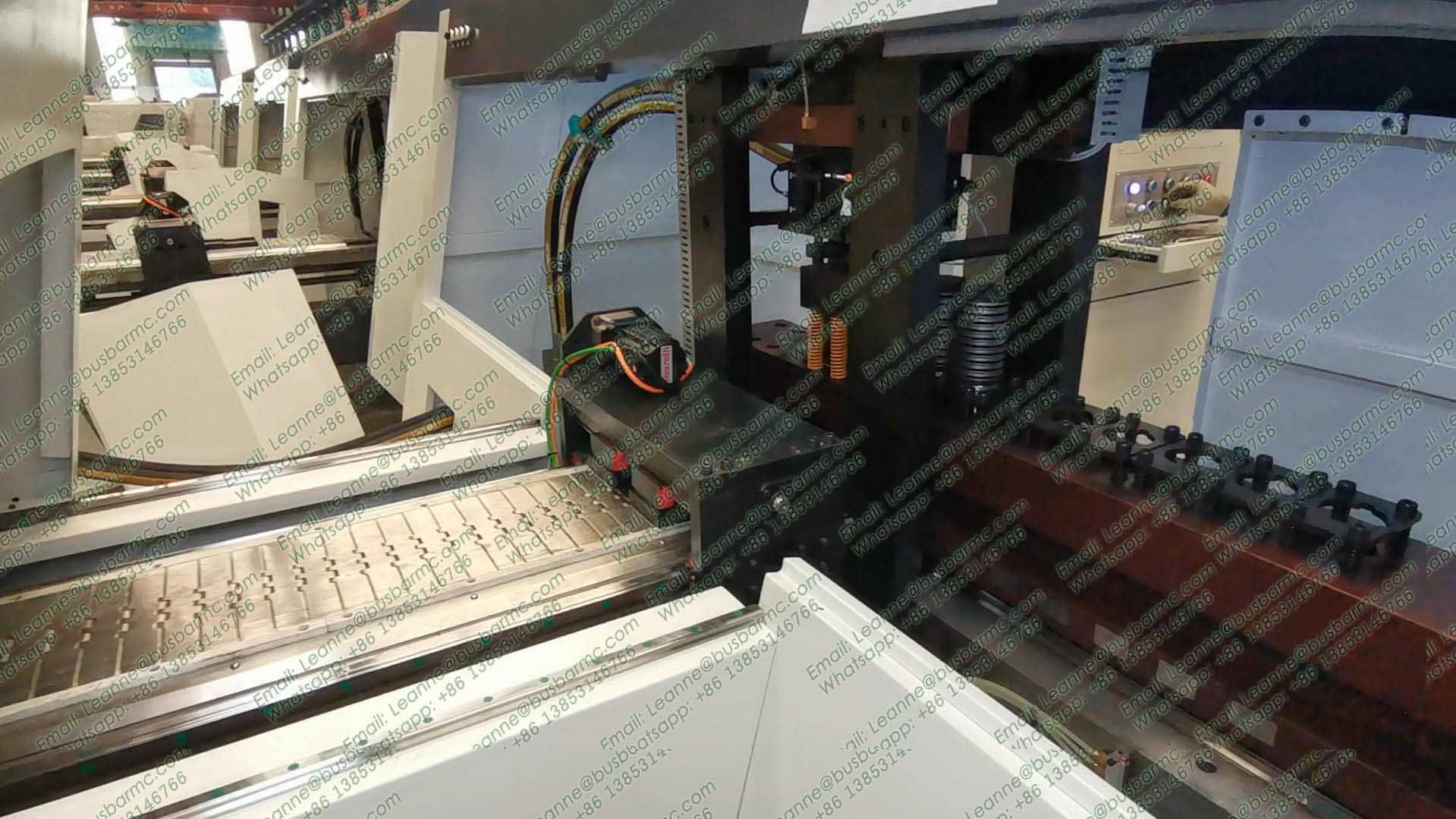

The LTMC HQ600-S-8P is a high-performance CNC Busbar Punching Machine designed for the Indian electrical manufacturing industry. It integrates precision Punching and Shearing functions into one automated system.

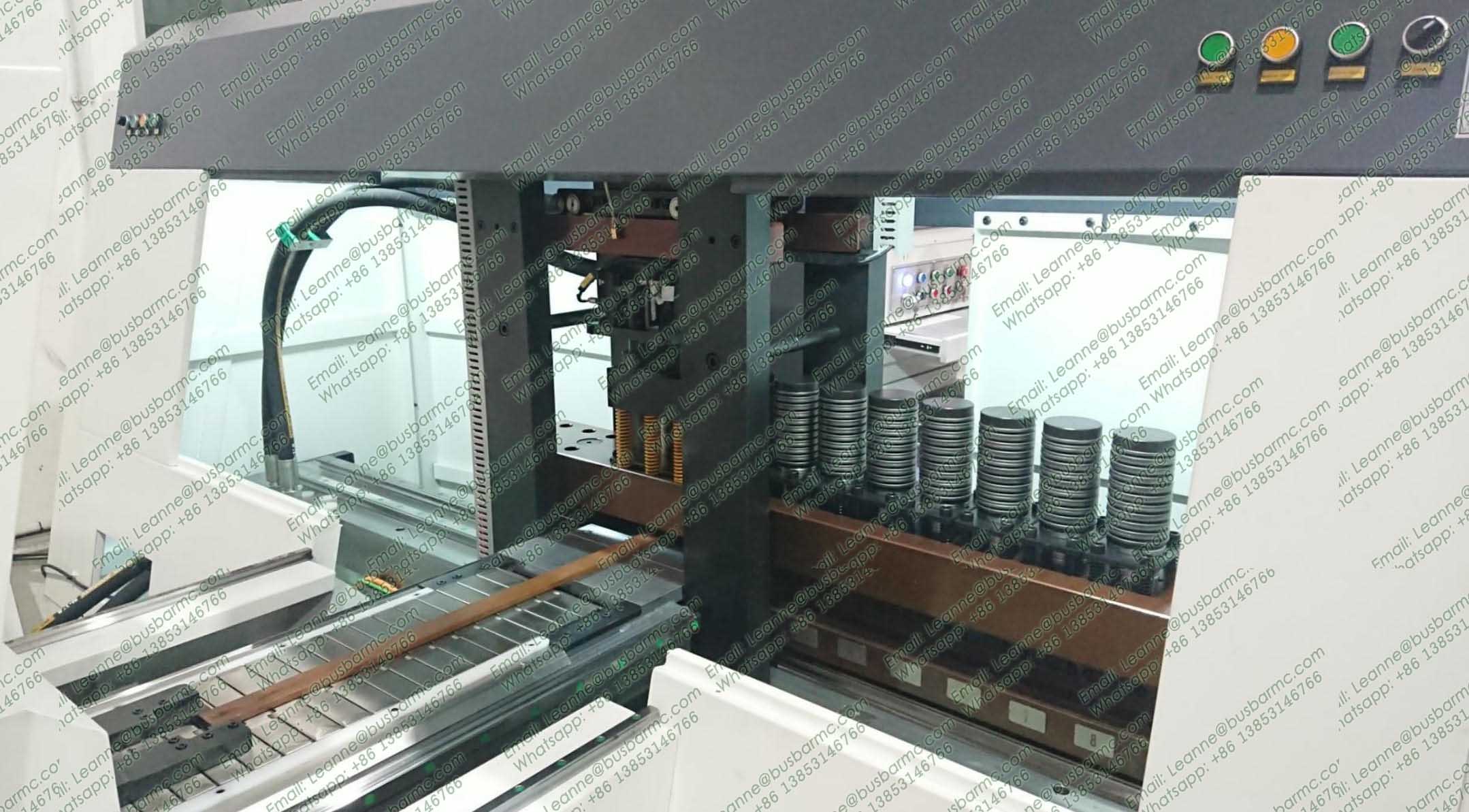

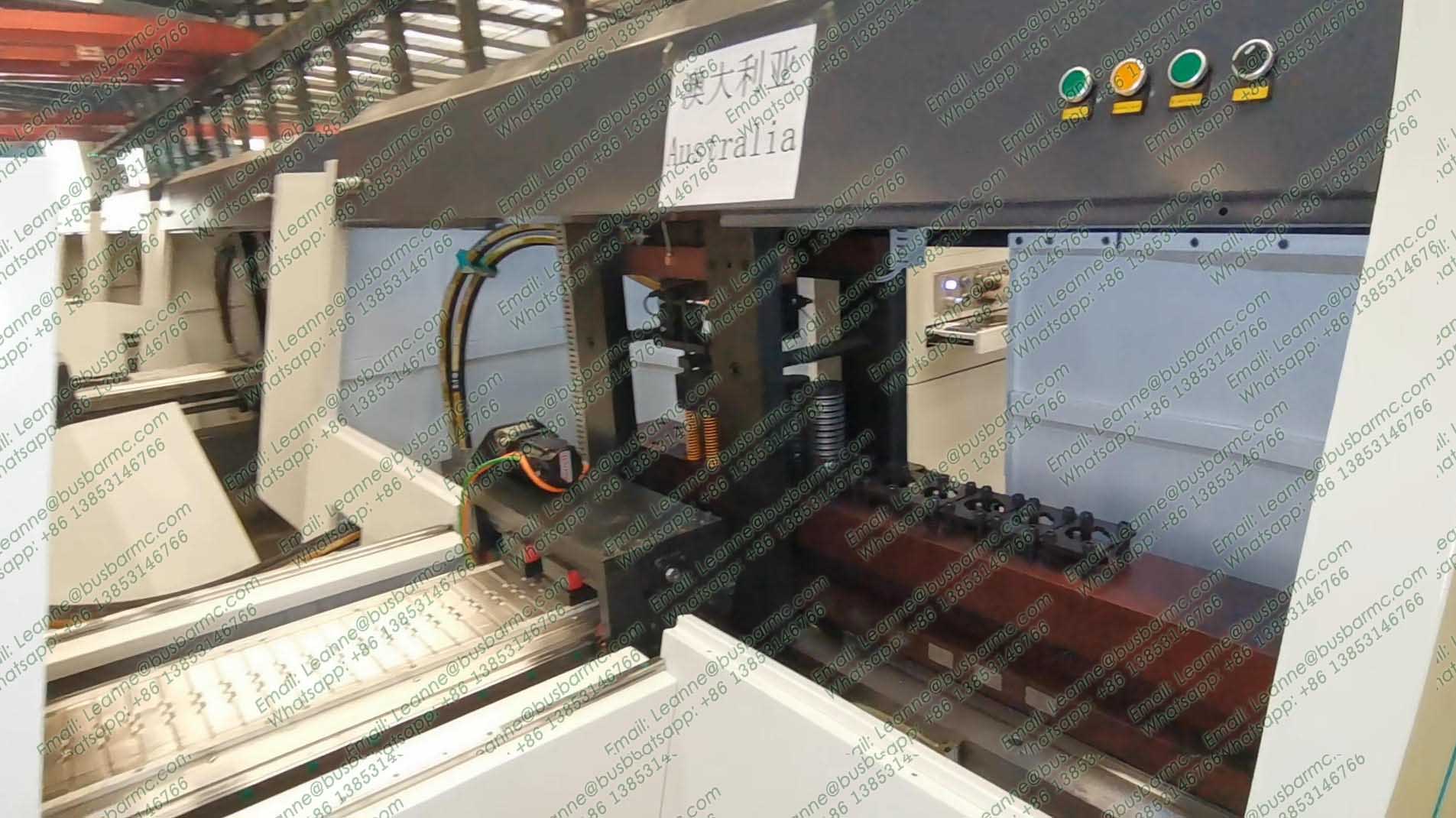

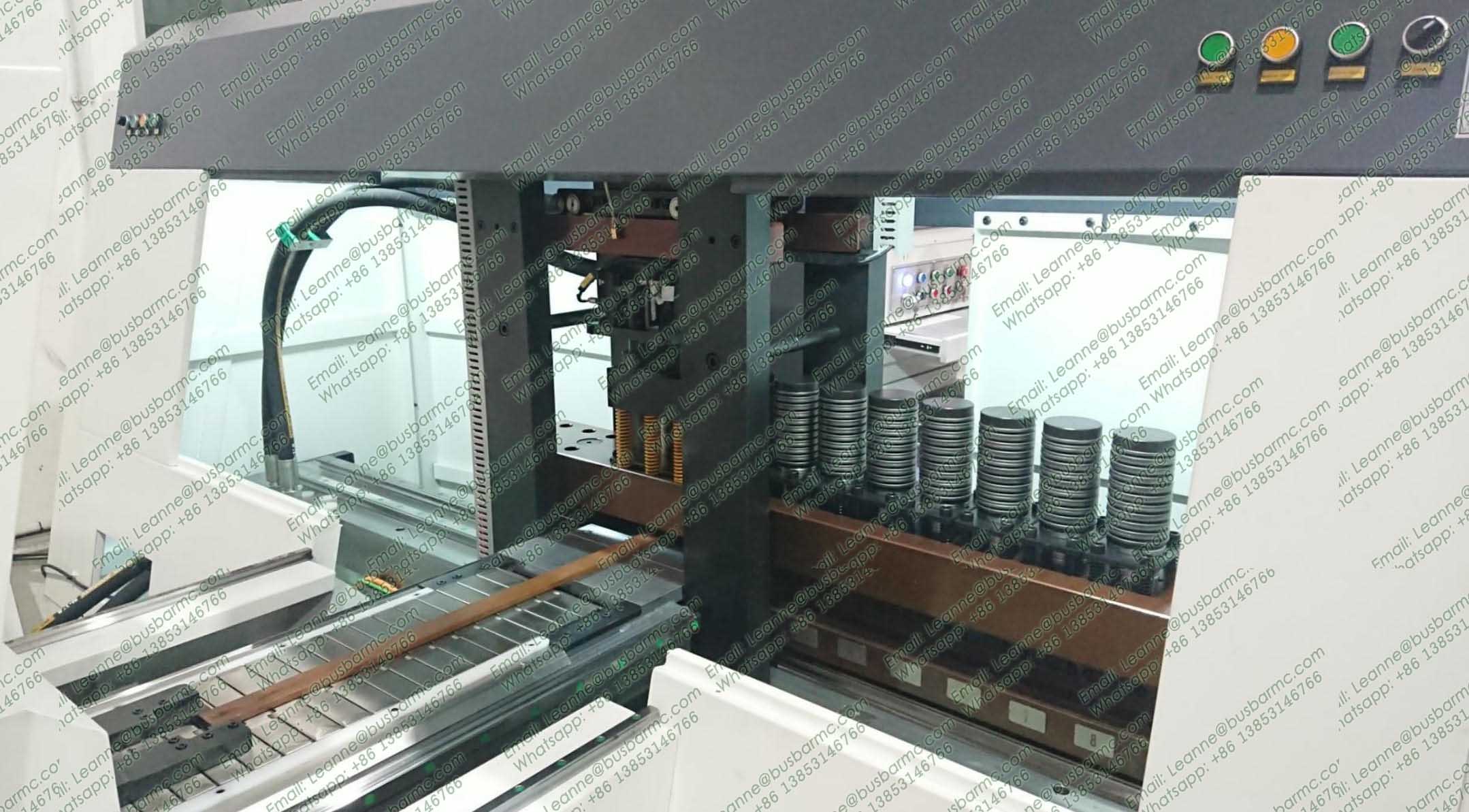

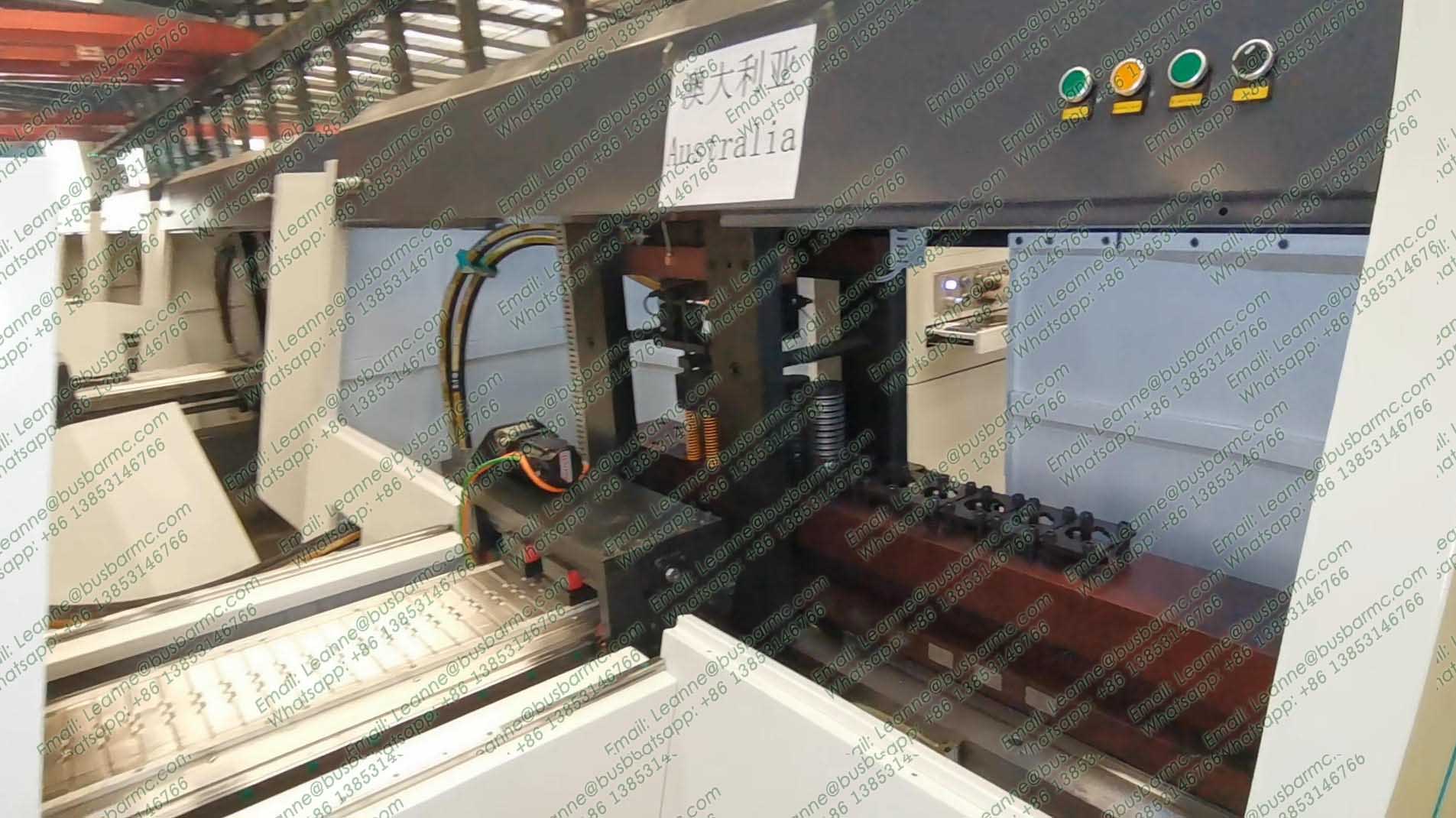

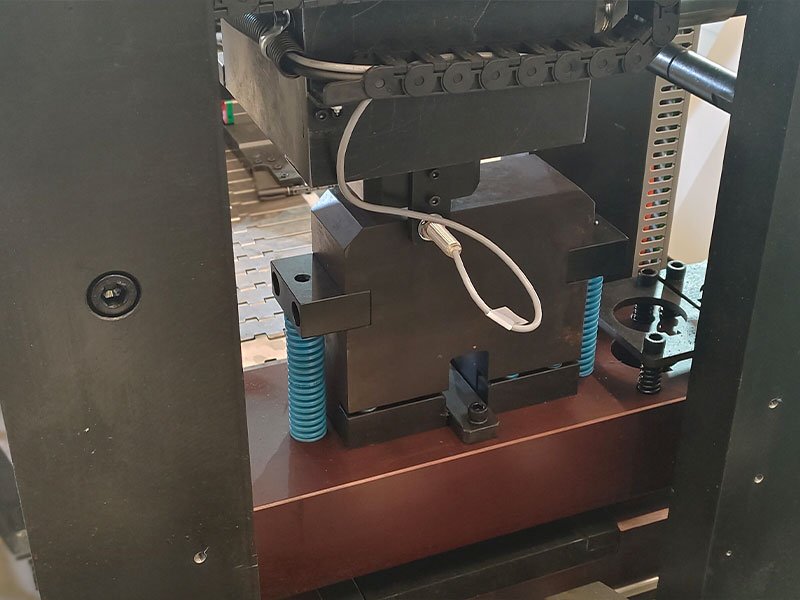

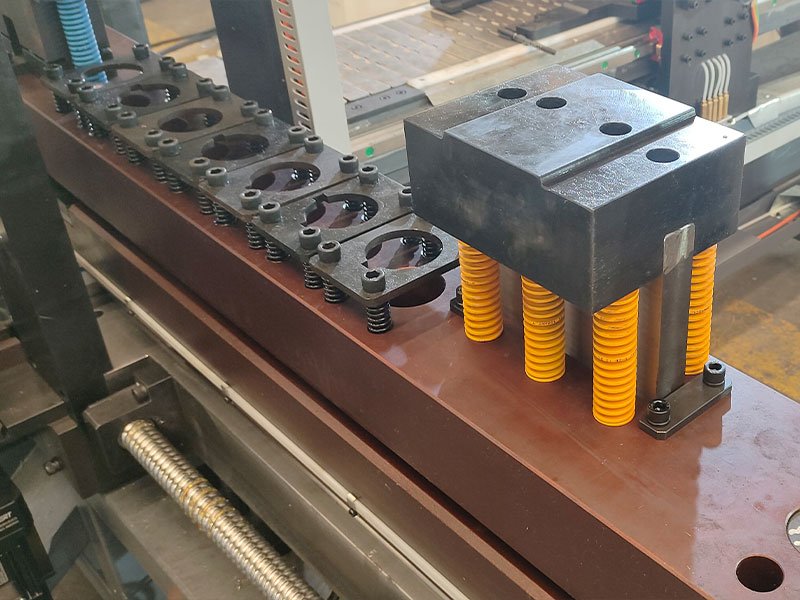

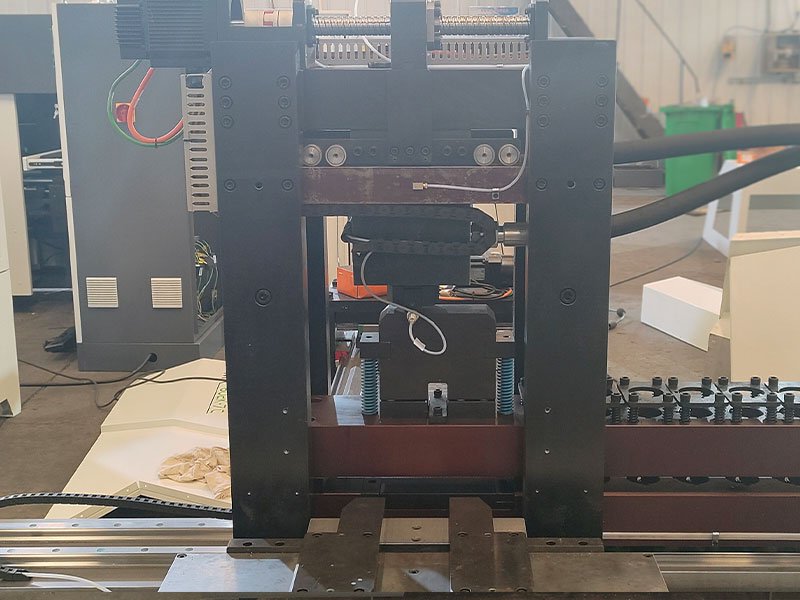

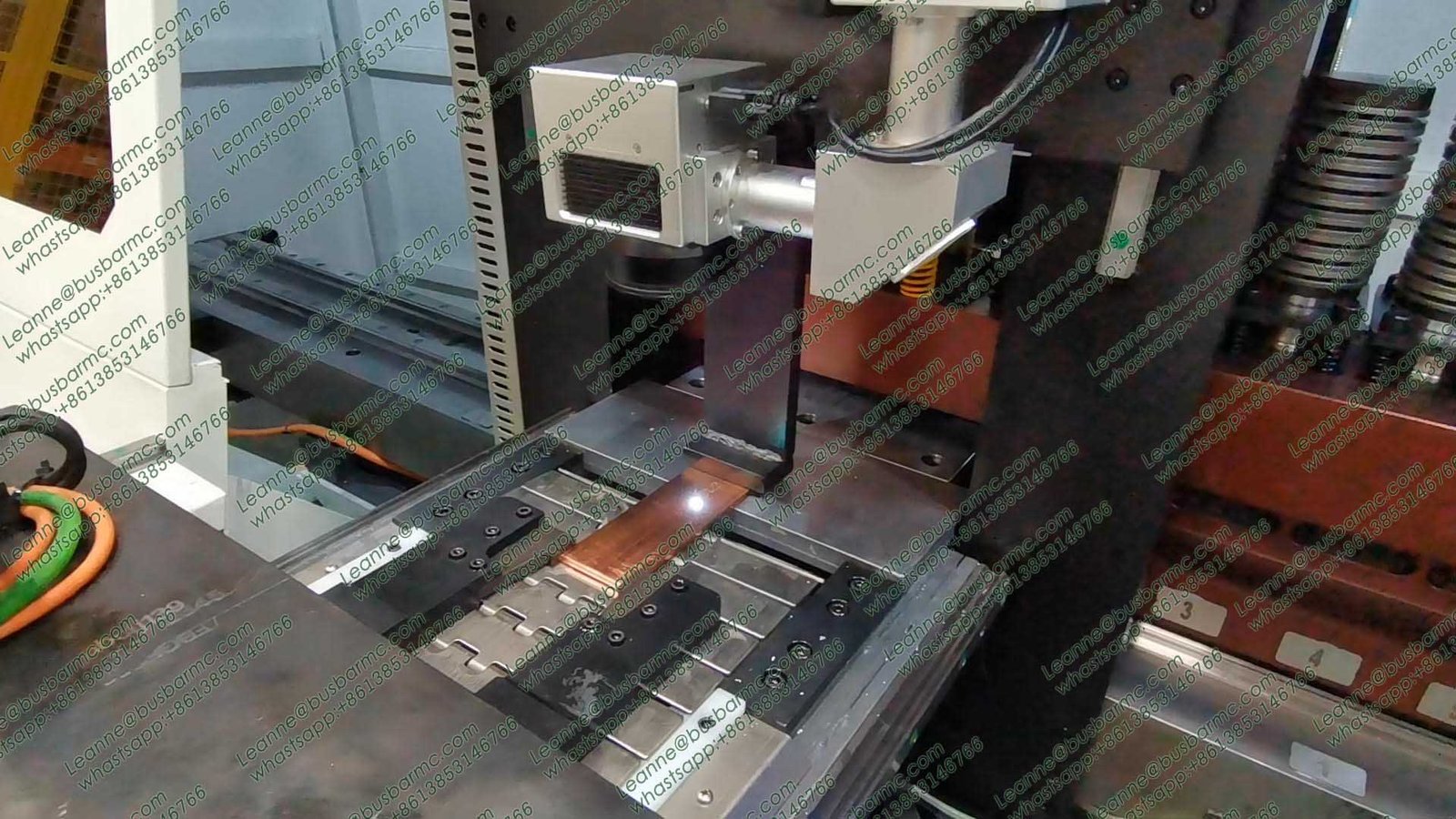

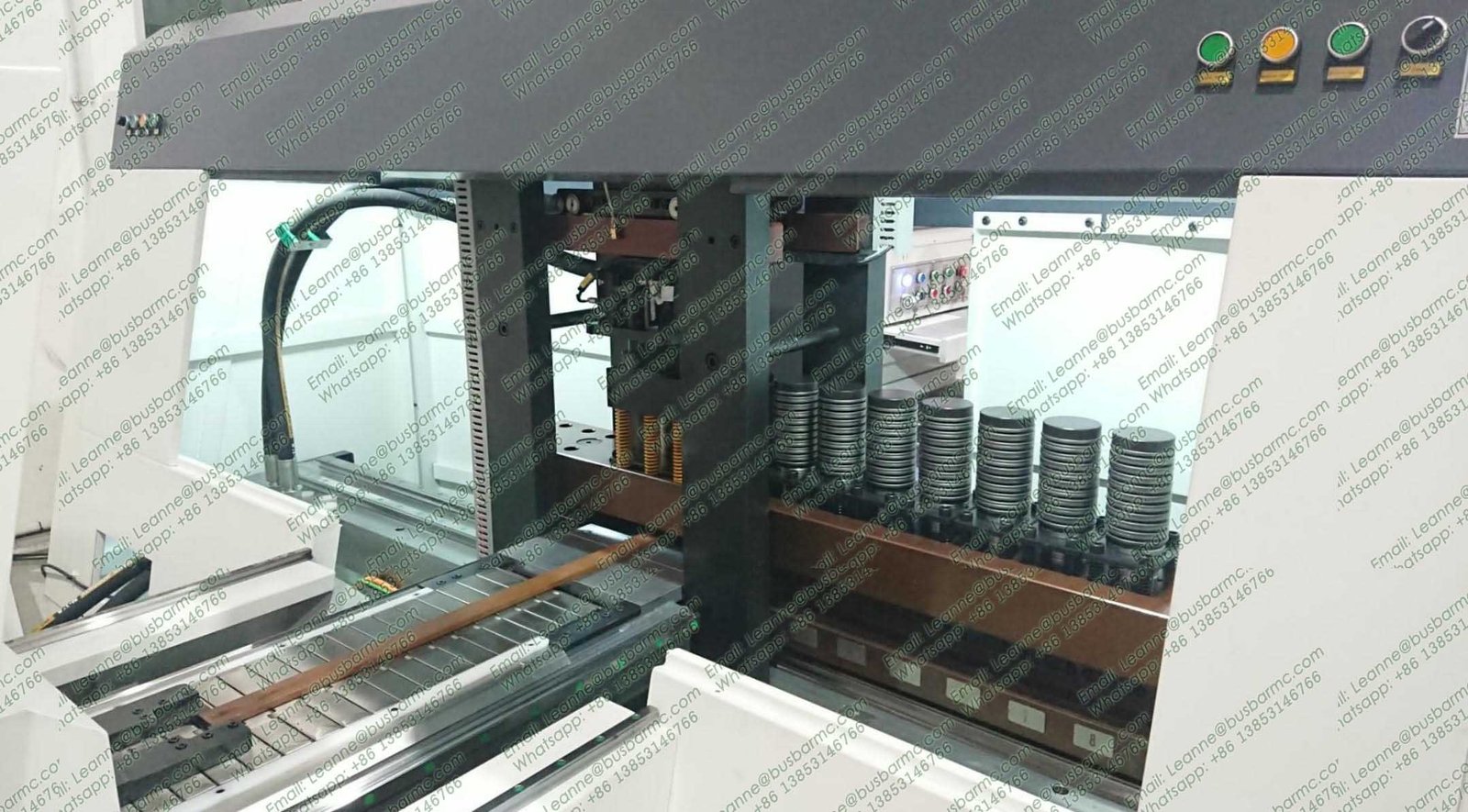

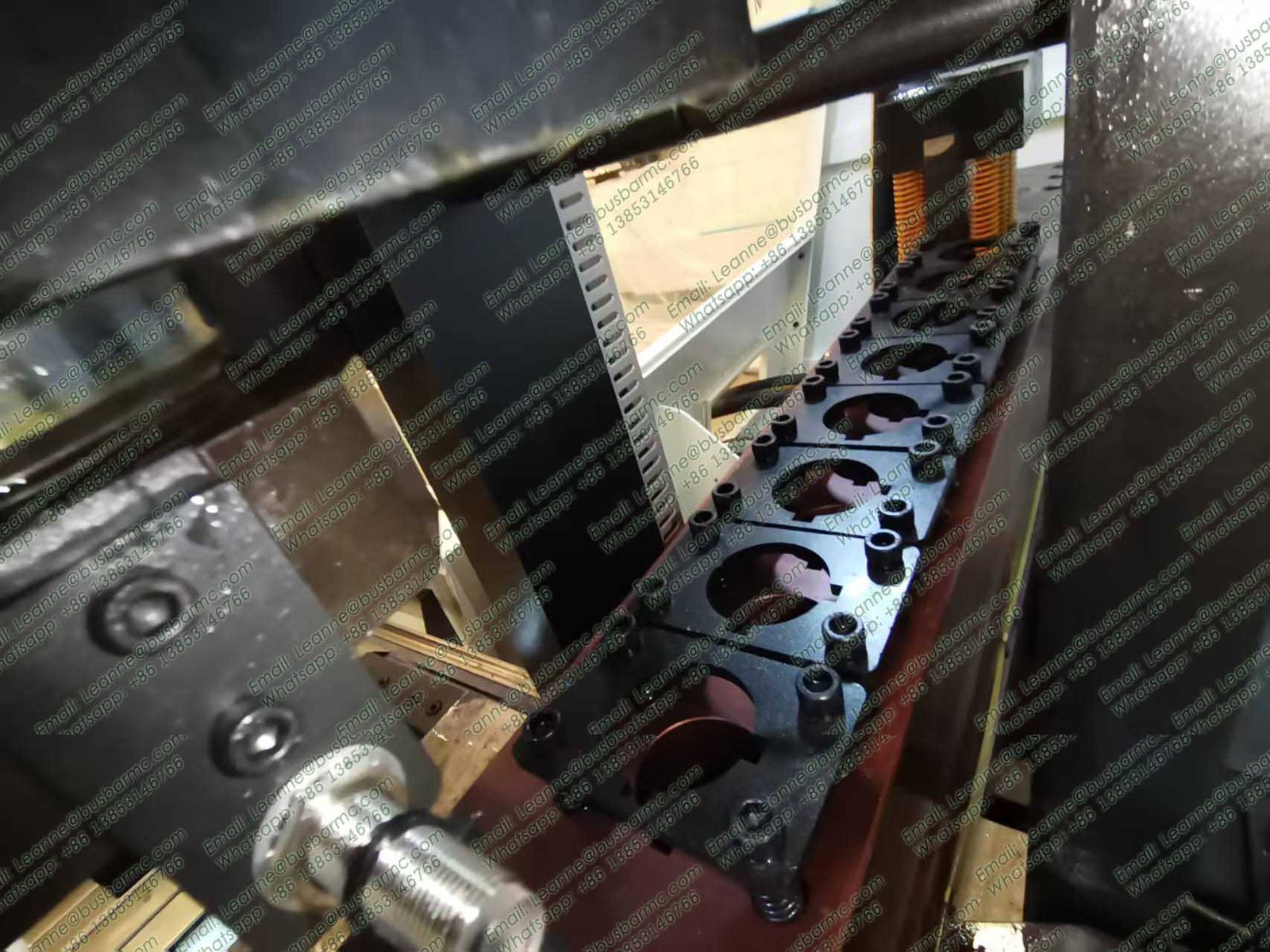

Featuring a robust Straight Column Mold Frame with an 8-Station Punching Turret and 1 Shearing Station, it ensures perfect concentricity of upper and lower dies during long-term operation.

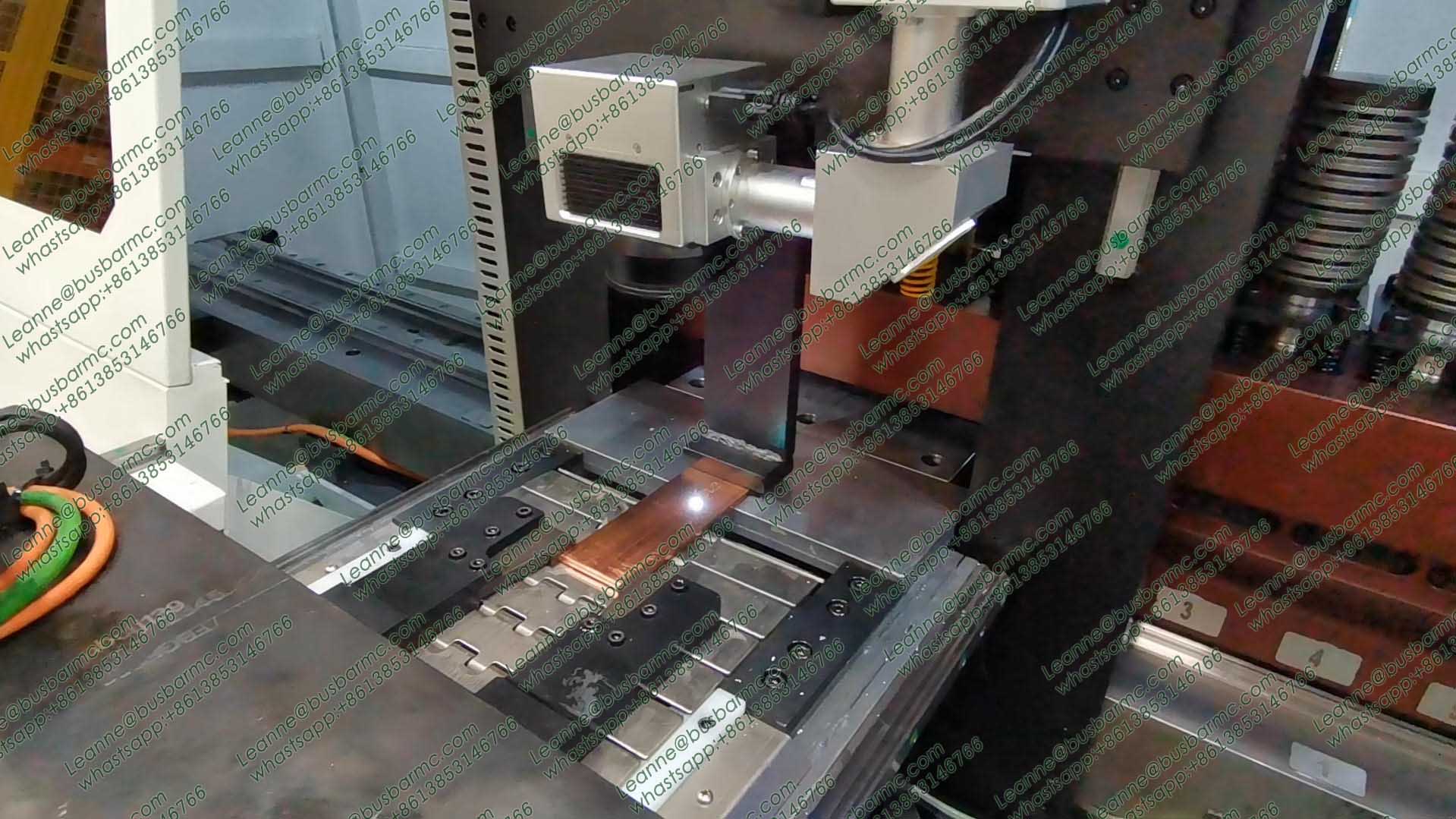

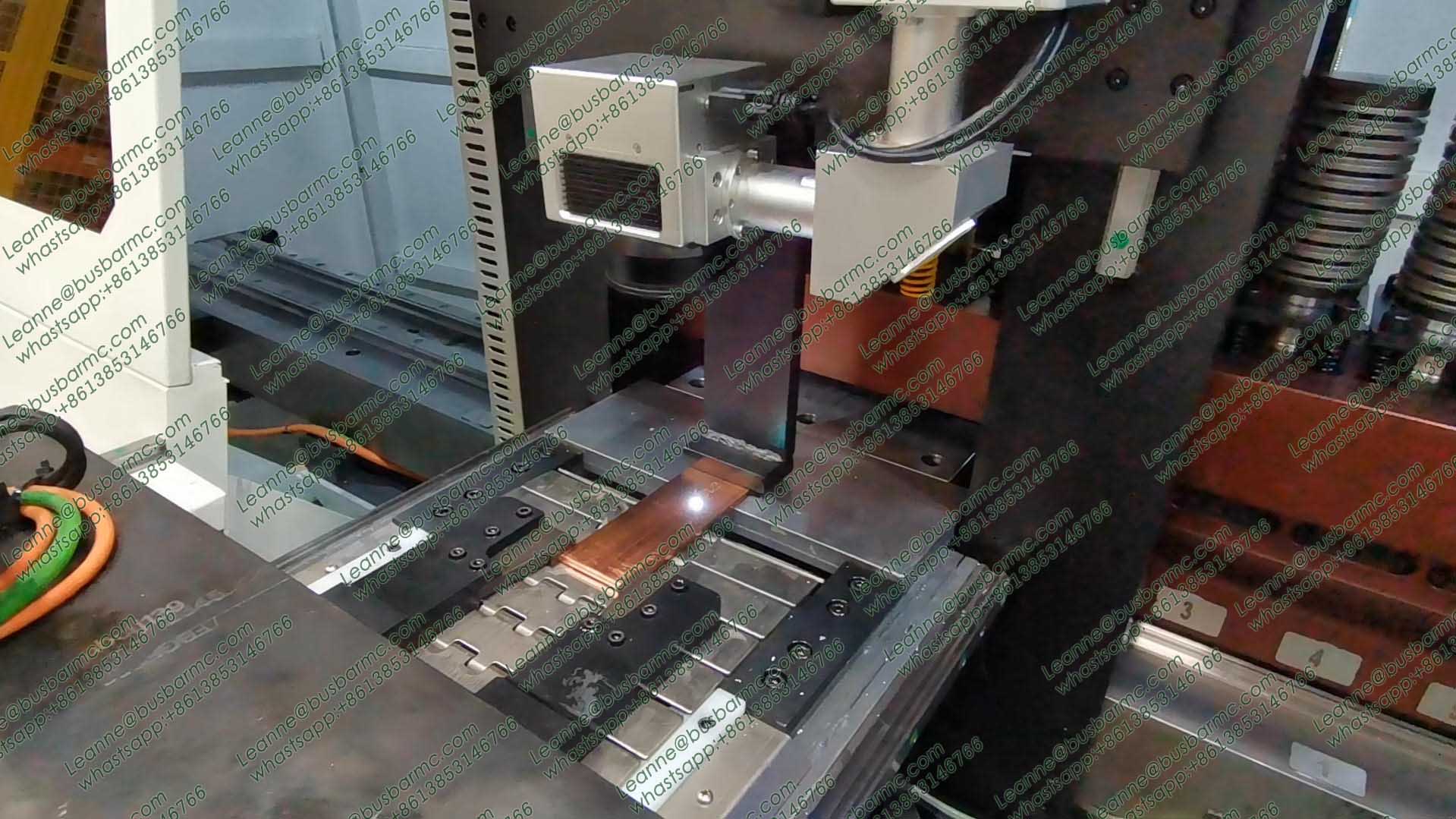

Equipped with an advanced CNC control system and CAD/CAM software, this machine drastically improves production efficiency for Copper and Aluminium busbars (Copper Patti & Aluminium Flats).

Contact us now for the latest CNC Busbar Punching Machine Price in India and technical specifications.

High Speed CNC Busbar Machine Demo Video:

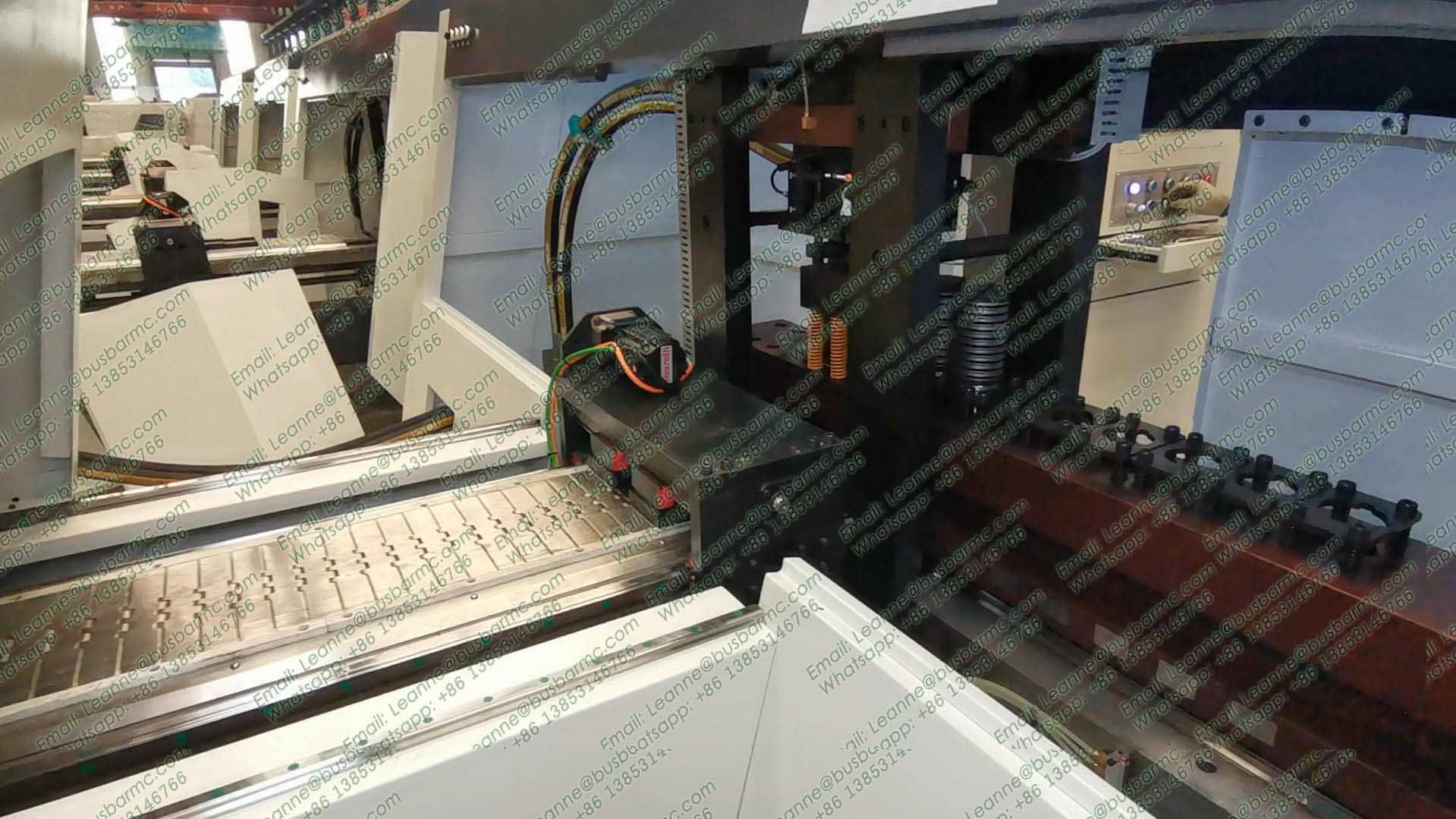

Machine Details & Factory View:

Main Features:

1. 8-Station Single Row Die Library (Turret):

The unique Straight Column design features 8 Punching Molds + 1 Shearing Mold in a single row. This ensures perfect concentricity for punching and shearing. It achieves a high efficiency of 40m/min with precision control up to 0.1mm/500mm.

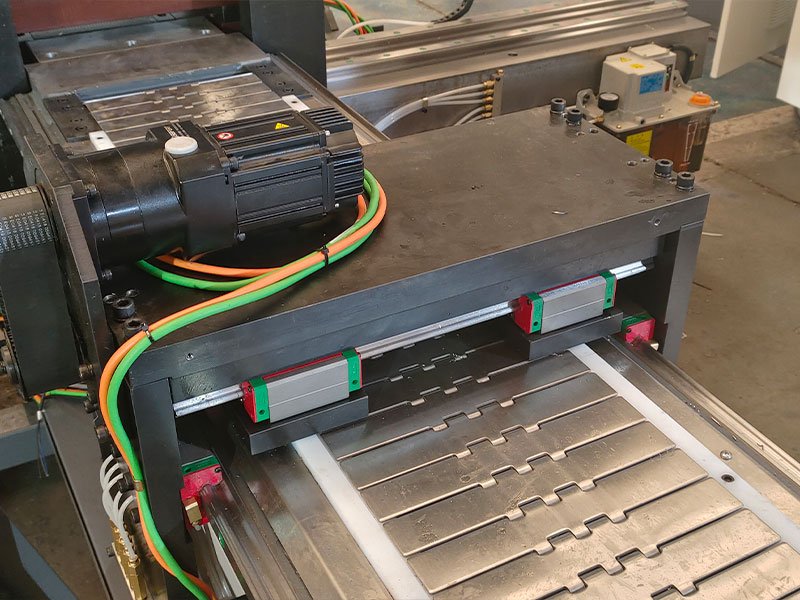

2. High Speed 6-Axis Servo System (Max 75m/min):

The machine utilizes a 6-Axis Motion Control System driven by 6 Servo Motors. With dual clamps (X1 stroke 110mm, X2 stroke 2000mm), it optimizes feeding and discharging strokes. The X-axis speed reaches up to 75m/min (150m/min no-load), significantly boosting productivity.

3. Powerful 600KN Hydraulic System (Swiss ABB Motor):

Equipped with a premium Swiss ABB Motor, the hydraulic station delivers a robust 600KN (60 Ton) pressure. This ensures stable and powerful punching/shearing force for thick copper busbars.

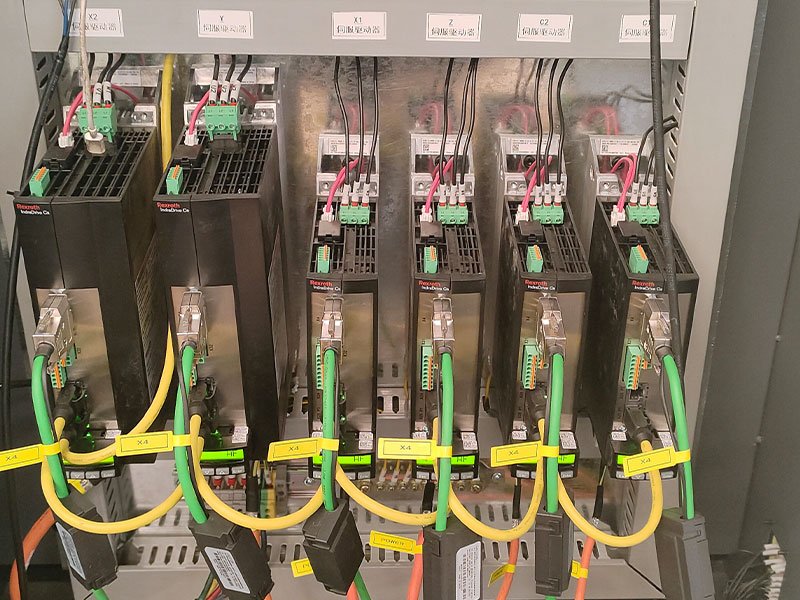

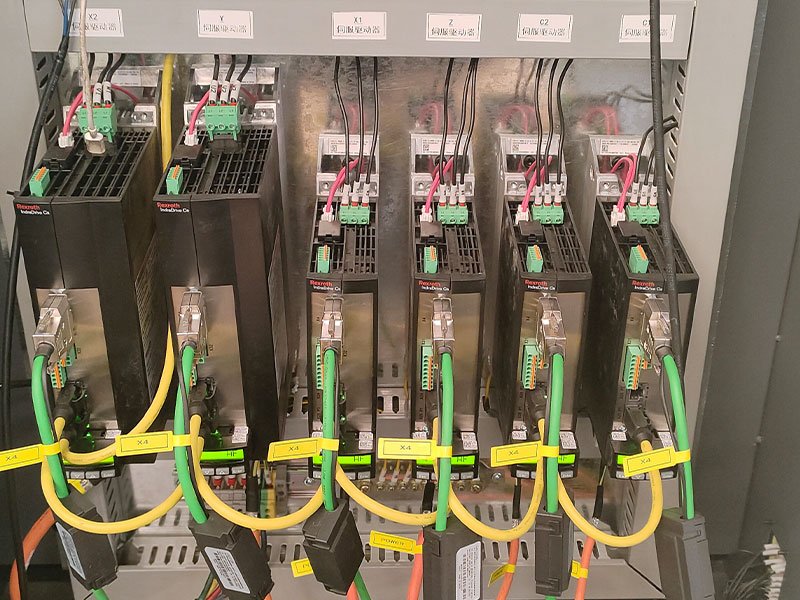

4. Premium Components (German Beckhoff & Rexroth):

It uses a German Beckhoff CNC System with closed-loop control for superior accuracy and anti-interference, surpassing standard open-loop systems. The Servo Motors and Drivers are from German Rexroth, ensuring long-term stability and lower maintenance costs.

Technical Specifications – HQ600-S-8P:

| Model | HQ600-S-8P |

| Maximum Force | 600KN (60 Ton) |

| Feeding Station Size | 3000x500mm |

| Discharge Station Size | 2500x500mm |

| Maximum Plate Size | 6000x200x15mm |

| Maximum Processing Thickness | 15mm |

| Maximum Processing Width | 200mm |

| Maximum Punching Diameter | Ø4.3-Ø55mm |

| Maximum Number of Cutting Dies | 1 |

| Maximum Number of Punching Dies | 8 |

| Max. Number of Embossing Mold | 0 (Customizable) |

| X-Axis Maximum Travel | 2000mm |

| X-Axis Accuracy Error | 0.10/500mm |

| Y-Axis Maximum Travel | 960mm |

| Y-Axis Accuracy Error | 0.10/500mm |

| Z-Axis Maximum Travel | 310mm |

| X-Axis Maximum Positioning Speed | 75m/min |

| Striking Cylinder Stroke | 45mm |

| Number of Control Axes | 6 |

| Dimensions (LxWxH) | 10500x2750x1800mm |

| Weight | 6700kg |

1. What is the HQ600-S-8P CNC busbar punching machine used for?

A: It is designed for high-efficiency punching and shearing of Copper and Aluminium busbars (Copper Patti & Aluminium Flats). Its 8-station turret allows for multiple hole sizes without changing dies, ideal for Switchgear and Transformer fabrication in India.

2. What is the maximum material size it can process?

A: It can handle busbars up to 6000mm length, 200mm width, and 15mm thickness.

3. How fast is the machine?

A: Thanks to the 6-Axis Servo System, the X-axis positioning speed reaches up to 75m/min (working) and 150m/min (no-load), making it one of the fastest in the market.

4. What control system does it use?

A: It uses a high-end German Beckhoff CNC system with closed-loop control for superior precision, along with Rexroth Servo Motors.

5. Does it support CAD drawings?

A: Yes, the included CAD/CAM software supports DXF drawing import, allowing for automatic programming of punching and shearing patterns.

6. How powerful is the hydraulic system?

A: It features a robust hydraulic station powered by a Swiss ABB Motor, delivering 600KN of force for clean punching and shearing.

7. What industries is this suitable for?

A: It is widely used in High/Low Voltage Switchgear, Power Distribution Cabinets, Transformer Manufacturing, Busduct Production, and Industrial Electrical Engineering.

CNC Busbar Punching Machine India, High Speed Copper Busbar Machine, Automatic Busbar Punching Cutting Machine, Hydraulic Busbar Machine Price, Heavy Duty Busbar Fabrication Equipment

Industry Keywords: HQ600-S-8P busbar machine, high speed CNC busbar punching machine, copper busbar processing machine, 8 station busbar turret punching machine, automatic busbar shearing machine, hydraulic busbar machine India, servo motor busbar machine, aluminum busbar punching machine, switchgear busbar fabrication machine, power distribution busbar equipment, high-precision busbar machining, industrial busbar equipment, electrical panel busbar machine, Beckhoff CNC busbar machine, Rexroth servo busbar machine, heavy-duty busbar workstation, electrical copper bar machine, programmable busbar machine, substation busbar processing equipment.