Achieve superior finish with the CNCDMN-200A CNC Busbar Chamfering Machine. Designed for Indian Switchgear & Transformer manufacturers, this fully Automatic system performs high-precision Milling, Arc Rounding, and Chamfering on Copper & Aluminium busbars. It creates smooth, burr-free R-angles and chamfers, essential for high-voltage panel safety. Easy programming and high-speed operation. Contact us today for the best Busbar Chamfering Machine Price in India.

CNCMN-200A Automatic CNC Busbar Chamfering Machine (Milling & Rounding)

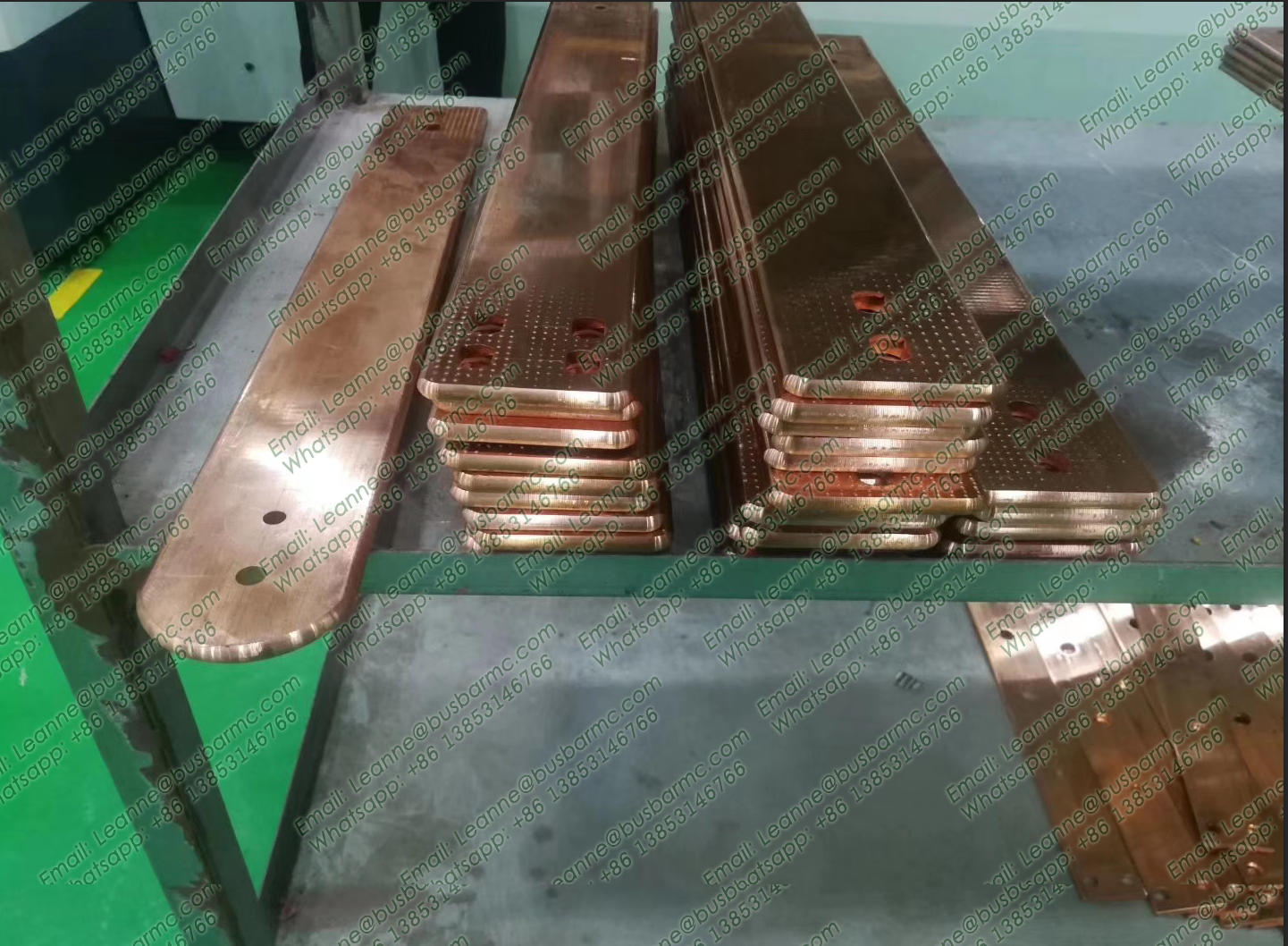

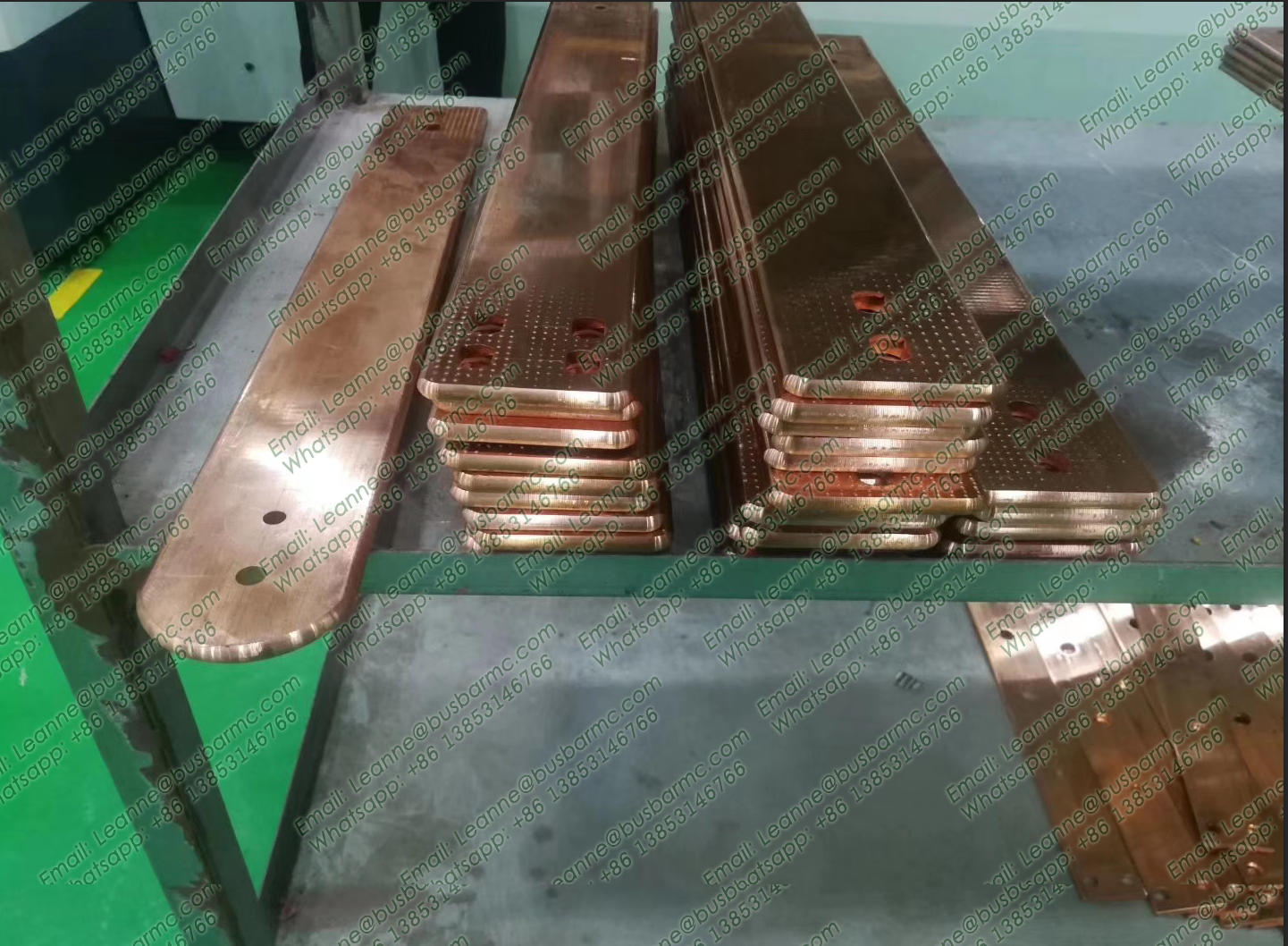

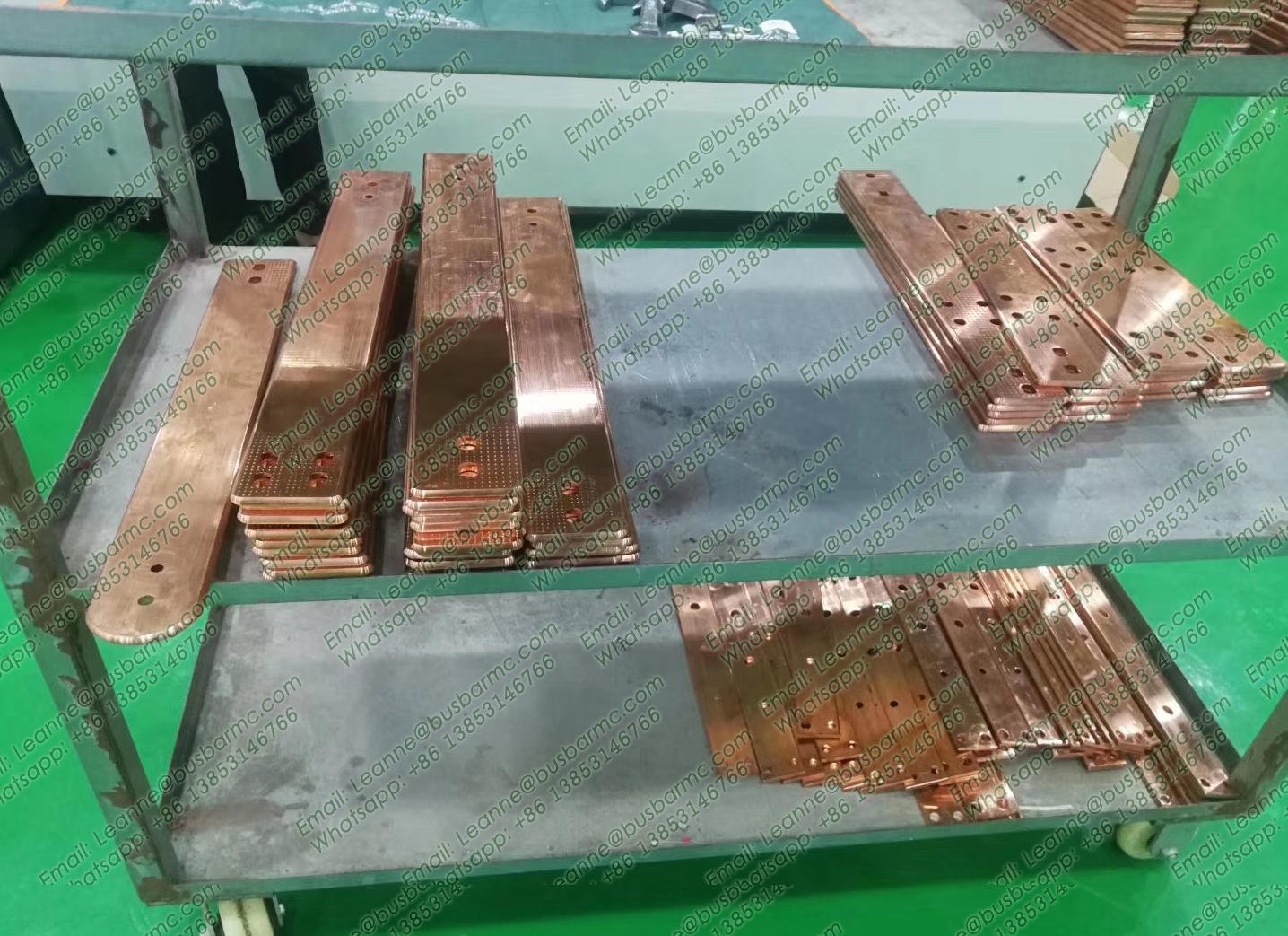

The main function of this CNC Busbar Arc Processing Center is to perform high-precision Chamfering, Milling, and Arc Rounding on the ends of Copper and Aluminium busbars (Copper Patti). It is an essential machine for Indian Switchgear manufacturers to ensure smooth, burr-free edges.

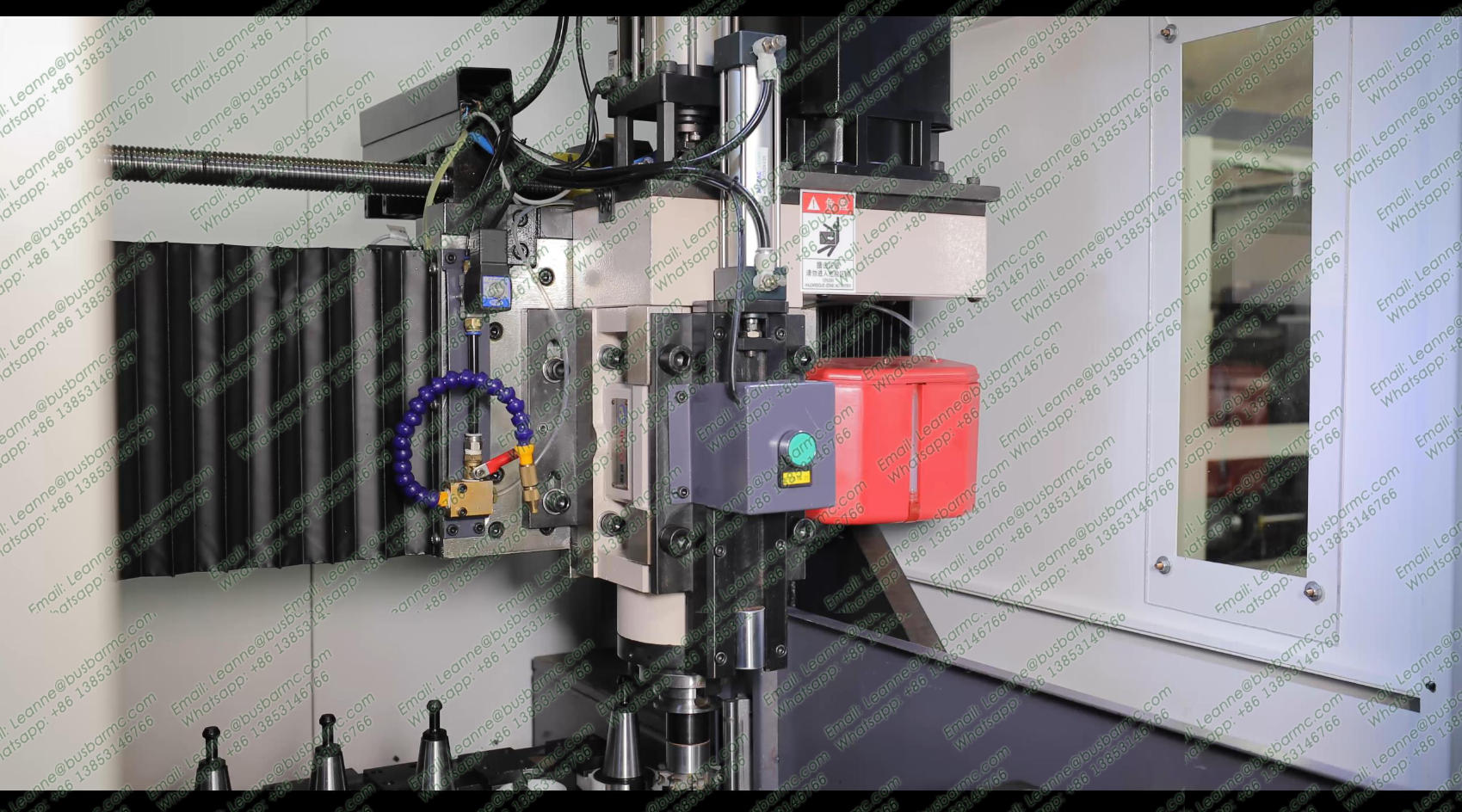

▲ Heavy Duty Gantry Structure: Simple design, stable operation, and excellent structural rigidity suitable for Indian industrial conditions.

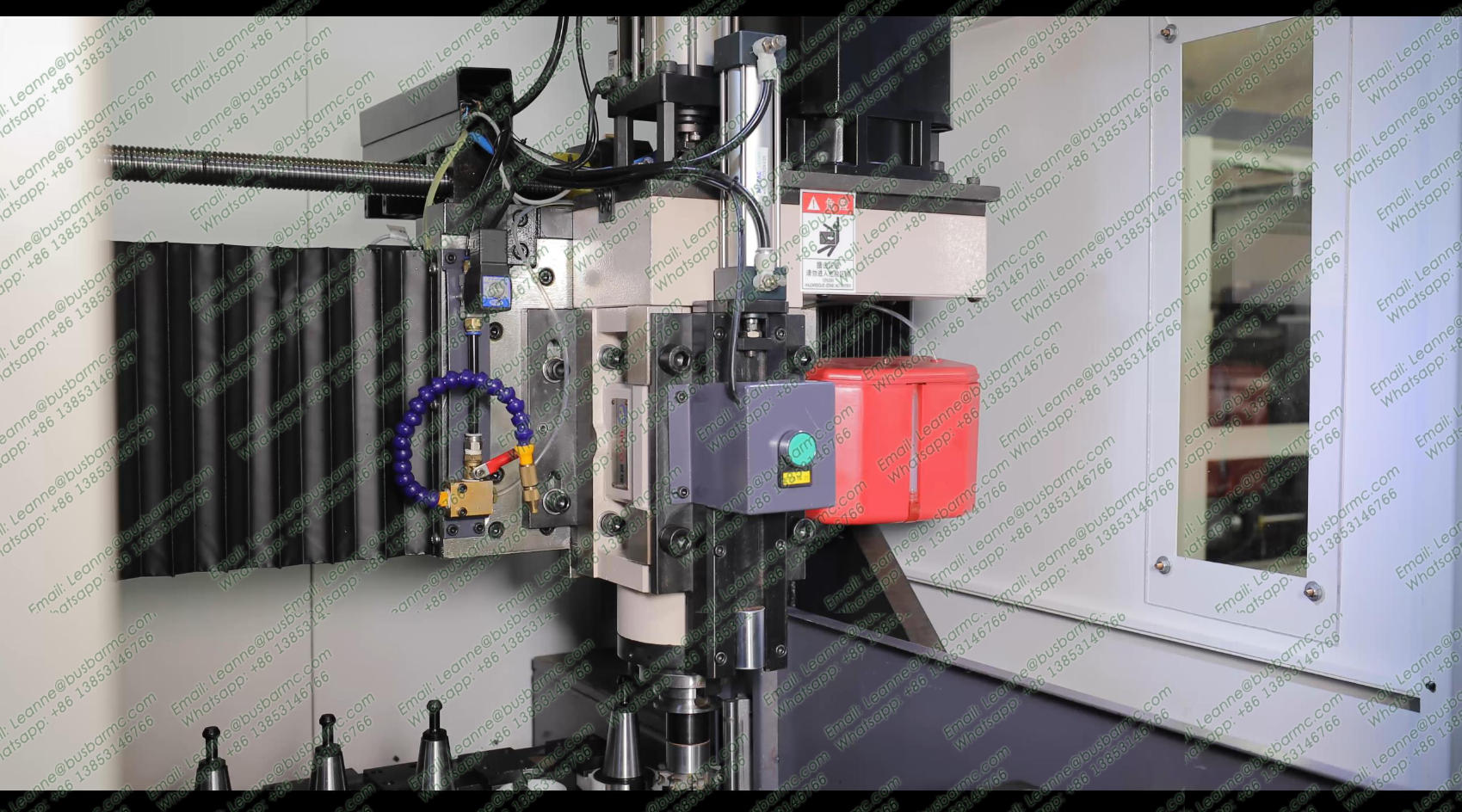

▲ Automatic Tool Change: Features a Six-station inline tool magazine for seamless switching between milling and chamfering tools.

▲ BT40 Tool Holder: Uses international standard BT40 holders, ensuring simple tool changes, high rigidity, and superior precision for busbar finishing.

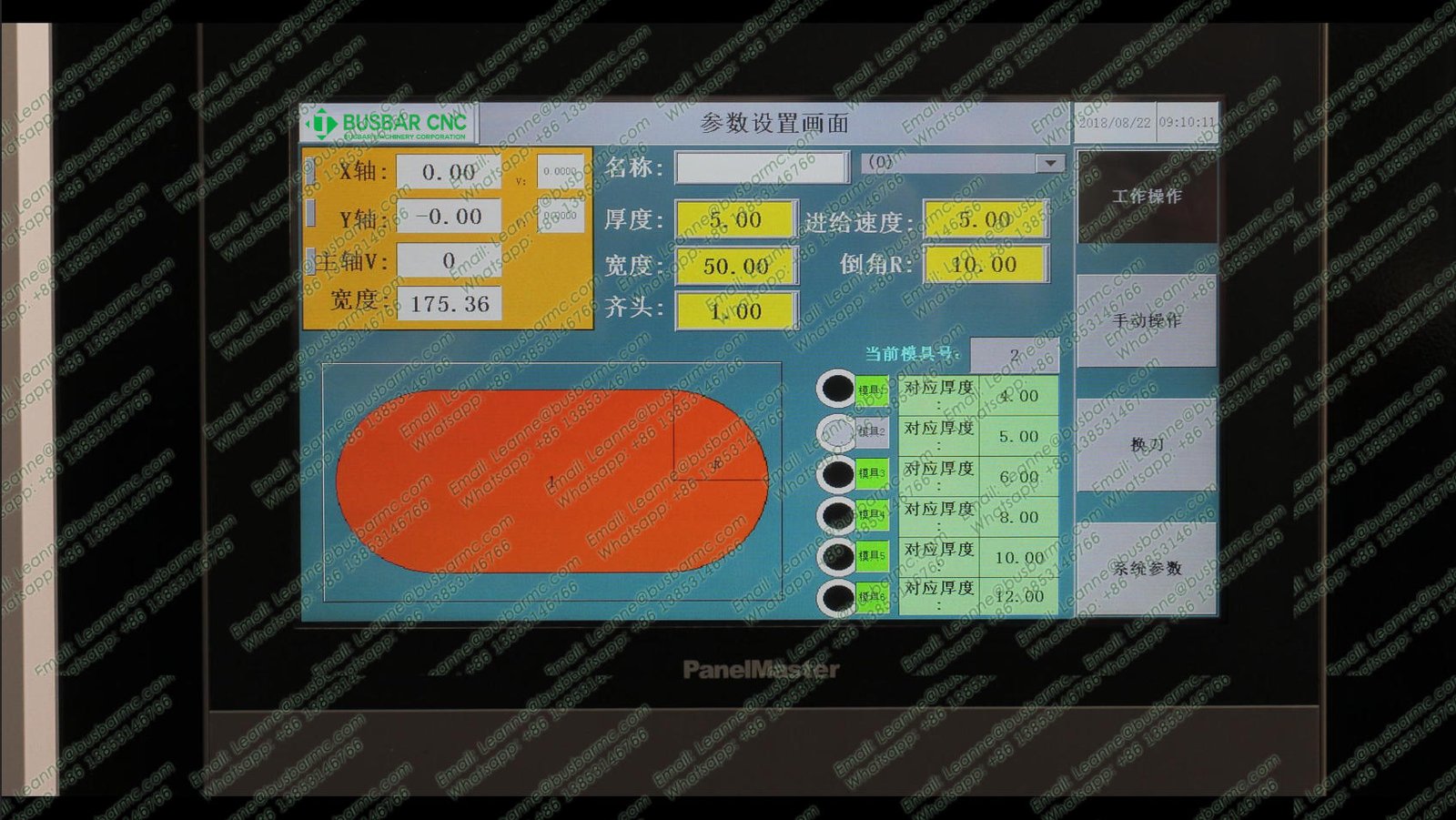

▲ Two-axis Control System: Simple operation and convenient maintenance, designed for ease of use by operators.

▲ HMI Interface: Clear Human-Machine Interface with simple operation logic.

| No. | Technical Parameters | Unit | Value | No. | Technical Parameters | Unit | Value |

|---|---|---|---|---|---|---|---|

| 1 | Maximum spindle speed | r/min | 6000 | 2 | Main motor power | KW | 3.7 |

| 3 | Maximum X-axis travel | mm | 525 | 4 | Maximum speed of X axis | m/min | 15 |

| 5 | X-axis positioning accuracy | mm | ±0.08 | 6 | Maximum travel of X axis | mm | 500 |

| 7 | Maximum Y-axis speed | m/min | 15 | 8 | Positioning accuracy of Y axis | mm | ±0.08 |

| 9 | Maximum Z-axis travel | mm | 130 | 10 | Positioning accuracy of Z axis | mm | ±0.05 |

| 11 | Workpiece length that can be processed | mm | 150-6000 | 12 | Machinable workpiece width | mm | 30-200 |

| 13 | Machinable workpiece thickness | mm | 4-16 | 14 | Dimensions | mm | 2260×1580×2100 |

Control Method Parameters:

| No. | Technical Parameters | Unit | Value | No. | Technical Parameters | Unit | Value |

|---|---|---|---|---|---|---|---|

| 1 | Number of CNC axes | PC | 5 | 2 | X-axis servo motor power | KW | 2 |

| 3 | Y-axis servo motor power | KW | 2 | 4 | Z-axis servo motor power | KW | 1 |

| 5 | Air source pressure | MPa | 0.6-0.8 | 6 | Hydraulic pump motor power | KW | 2 |

| 7 | Total power | KW | 12 | ||||

Machine Details & Application Info:

1. Main Purpose in India:

The primary function of this machine is to perform Arc Milling and Chamfering on the ends of copper bars (Copper Patti). It is used for milling angles, arc angles (R-angle), and other external profile processing of Copper and Aluminium busbars with a thickness of 4-16mm and a width of 30-200mm.

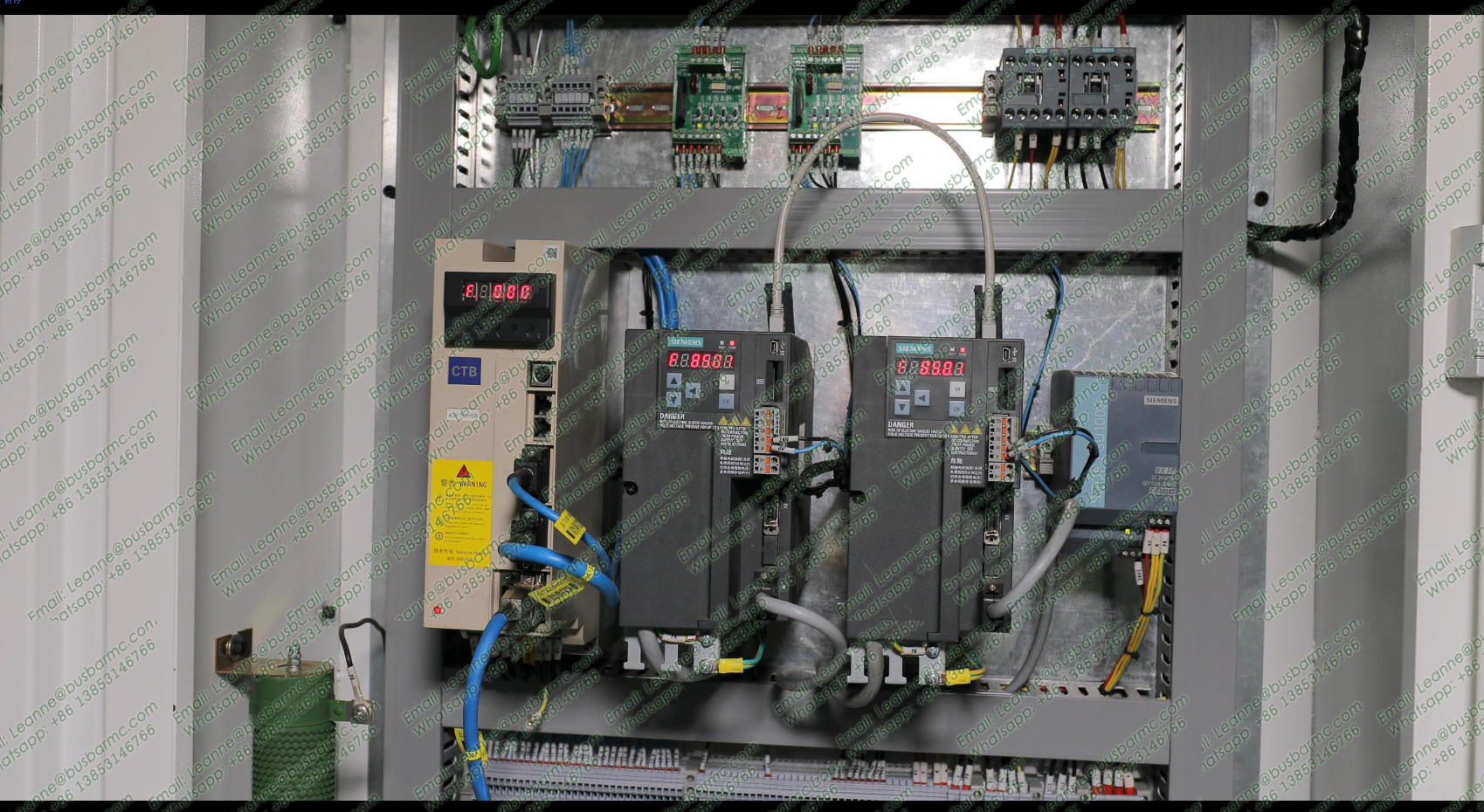

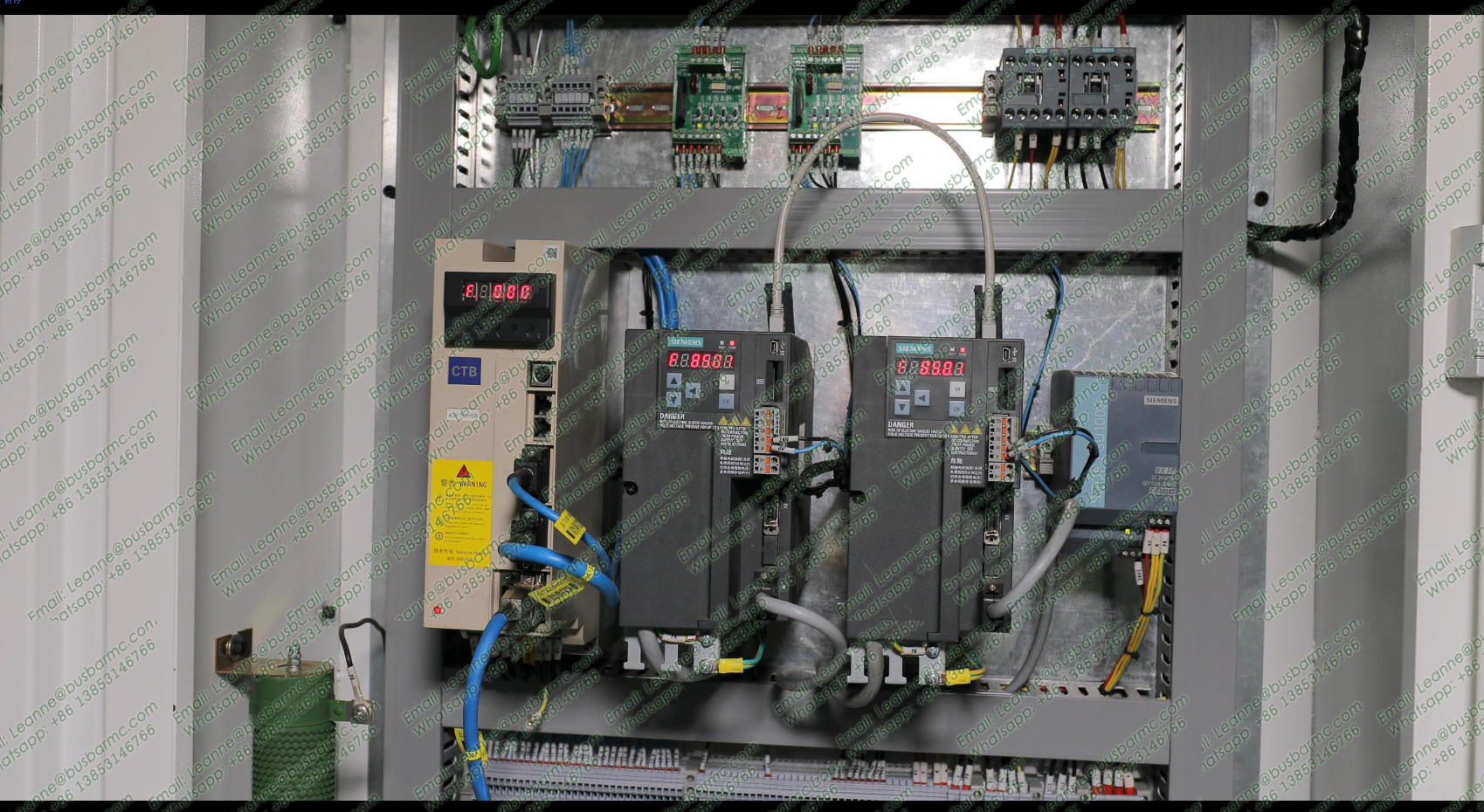

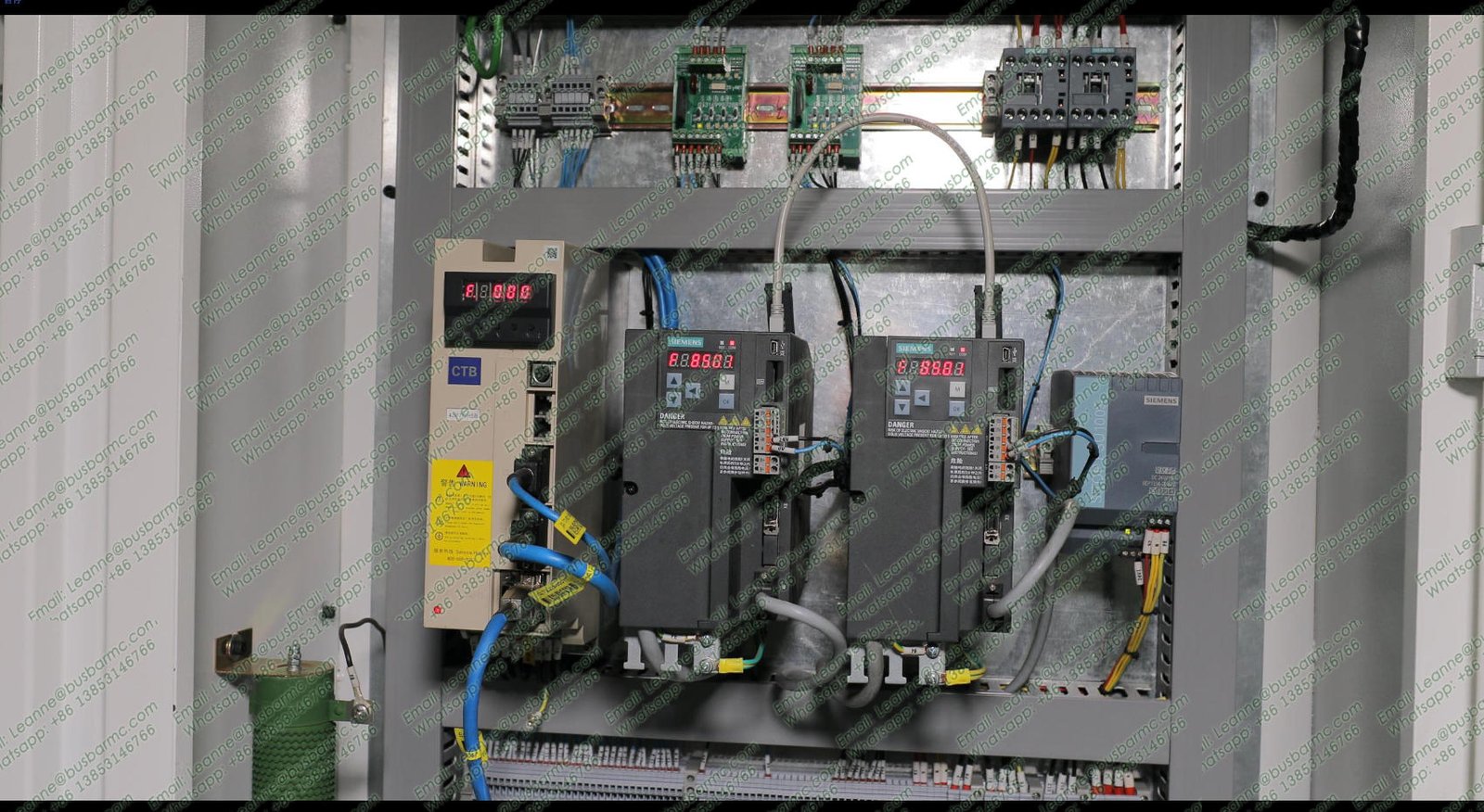

2. Control Method:

The machine uses a sophisticated 5-axis CNC system. Feeding and cutting are driven by the spindle motor and servo motors, while tool clamping is managed by pneumatic control.

Equipped with a 10.4″ LCD Display, the system allows for workload counting, storage of programs, simulation of processing, and easy manual online programming, making it user-friendly for Indian operators.

3. Machine Structure & Advantages:

Gantry Structure: The machine features a box-type gantry structure made of fully welded steel plates. This ensures high rigidity and stability, essential for heavy-duty milling of copper and aluminium busbars.

High Precision Guides: Equipped with high-precision Ball Screws and Linear Guides (Hiwin/TBI), ensuring smooth movement, reduced vibration, and high accuracy during operation.

Spindle System: The high-speed milling spindle is driven by a variable frequency motor with a synchronous belt drive, offering high cutting speeds without the need for complex lubrication.

Clamping System: A three-point positioning method with Pneumatic and Hydraulic Double Clamping ensures the copper bar is held securely without damage.

Protection & Chip Removal: The Y-axis guide is protected by accordion covers. The machine includes a Water Circulation System and an Automatic Chip Removal System with a collection trolley, keeping the workspace clean.

Main equipment components and supplier information

| NO | Name | Brands | QTS |

|---|---|---|---|

| 1 | Central Processing Unit (PLC) | Beckhoff, Germany | 1 |

| 2 | Servo Motor | Rexroth, Germany | 3 |

| 3 | Servo Drive | Rexroth, Germany | 3 |

| 4 | Ball Screw | TBI, Taiwan | 3 |

| 5 | Linear Rolling Guide | Hiwin, Taiwan | 3 |

| 6 | Pneumatic Parts | HSBC | 1 |

| 7 | Hydraulic Parts | Shanghai Fengyi | 1 |

| 8 | Spindle | Jingyao | 1 |

CNCMN-200A Machine Video Demo:

Q1: What is the main application of this machine in India?

It is used for high-precision chamfering, arc milling (Rounding), and edge finishing of Copper and Aluminium busbars (Copper Patti) for Switchgear and Transformer panels.

Q2: Can it process both Copper and Aluminium?

Yes, it is designed to process both Copper and Aluminium busbars efficiently with thickness ranging from 4mm to 16mm.

Q3: Does it support automatic tool changing?

Yes, it features a 6-station inline tool magazine that automatically changes BT40 tools based on the busbar thickness and processing requirements.

Q4: What is the maximum length of busbar it can handle?

It can process busbars with lengths from 150mm up to 6000mm, making it suitable for long busbars used in power distribution.

Q5: How does the chip removal system work?

The machine includes an automatic chip removal system with a water circulation function and a collection trolley to keep the workspace clean and safe.