Maximize your switchgear production with our CNC Double Table Busbar Processing Machine. This "Double Decker" design features independent stations, allowing simultaneous Punching, Shearing, and Bending of Copper & Aluminium busbars without interference. Equipped with PLC control for high precision, it is the ideal solution for Indian Panel Builders requiring heavy-duty performance. Contact us today for the best Double Table Busbar Machine Price in India.

CNC Double Table Busbar Processing Machine (Double Decker)

Product Description:

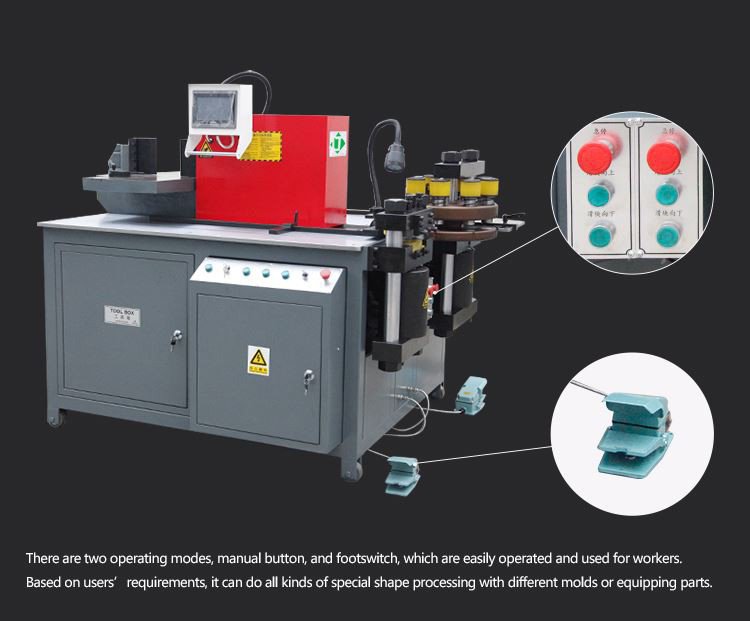

This CNC Double Table Busbar Processing Machine features three independent units: Punching, Shearing (Cutting), and Bending.

Known as the "Double Decker" in the Indian market, its unique design allows simultaneous operation of Punching/Shearing and Bending stations without interference. It is designed to shorten processing time and improve production efficiency for Copper and Aluminium busbars (Copper Patti & Aluminium Flats).

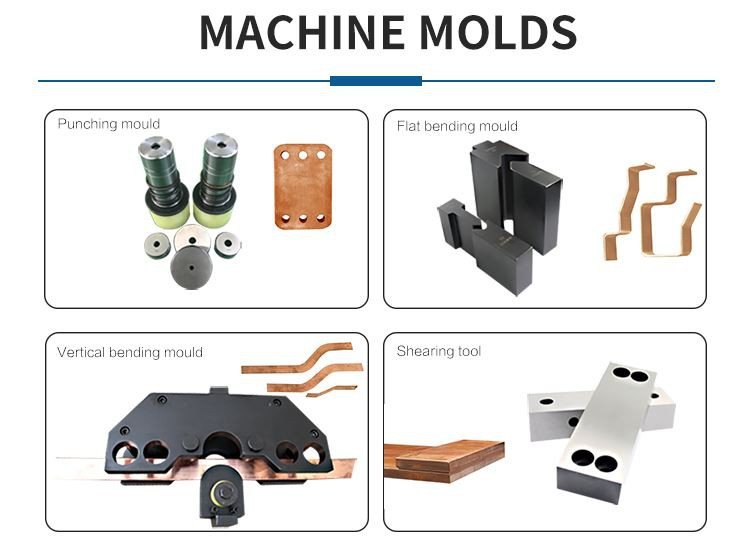

By changing molds, it can easily perform Shearing, Punching (Circular/Oblong holes), Flat/Horizontal Bending, Vertical Bending, U-Bending, Embossing, and Twisting.

Main Characteristics for Mass Production:

1. Shearing Unit: Uses a sharp shearing method. The incision interface is flat with no droop, no burrs, and no waste, saving expensive Copper material.

2. Turret Punching Unit: Equipped with a United Eight-Mode Turnplate (Turret). This robust design ensures perfect alignment, extends mold life, and eliminates frequent mold changes, reducing labor intensity significantly.

3. Double-Deck Bending Station: The true "Double Decker" design ensures that the Bending unit works on a separate level from Punching/Shearing. This guarantees Simultaneous Operation of all three stations. The open bending structure makes it very convenient to pick out the processed copper busbar.

4. Mobility & Control: The machine has four heavy-duty casters for easy movement. It offers two operating modes: Manual Button and Foot Switch, providing flexibility for workers. Custom molds can be installed for special shape processing.

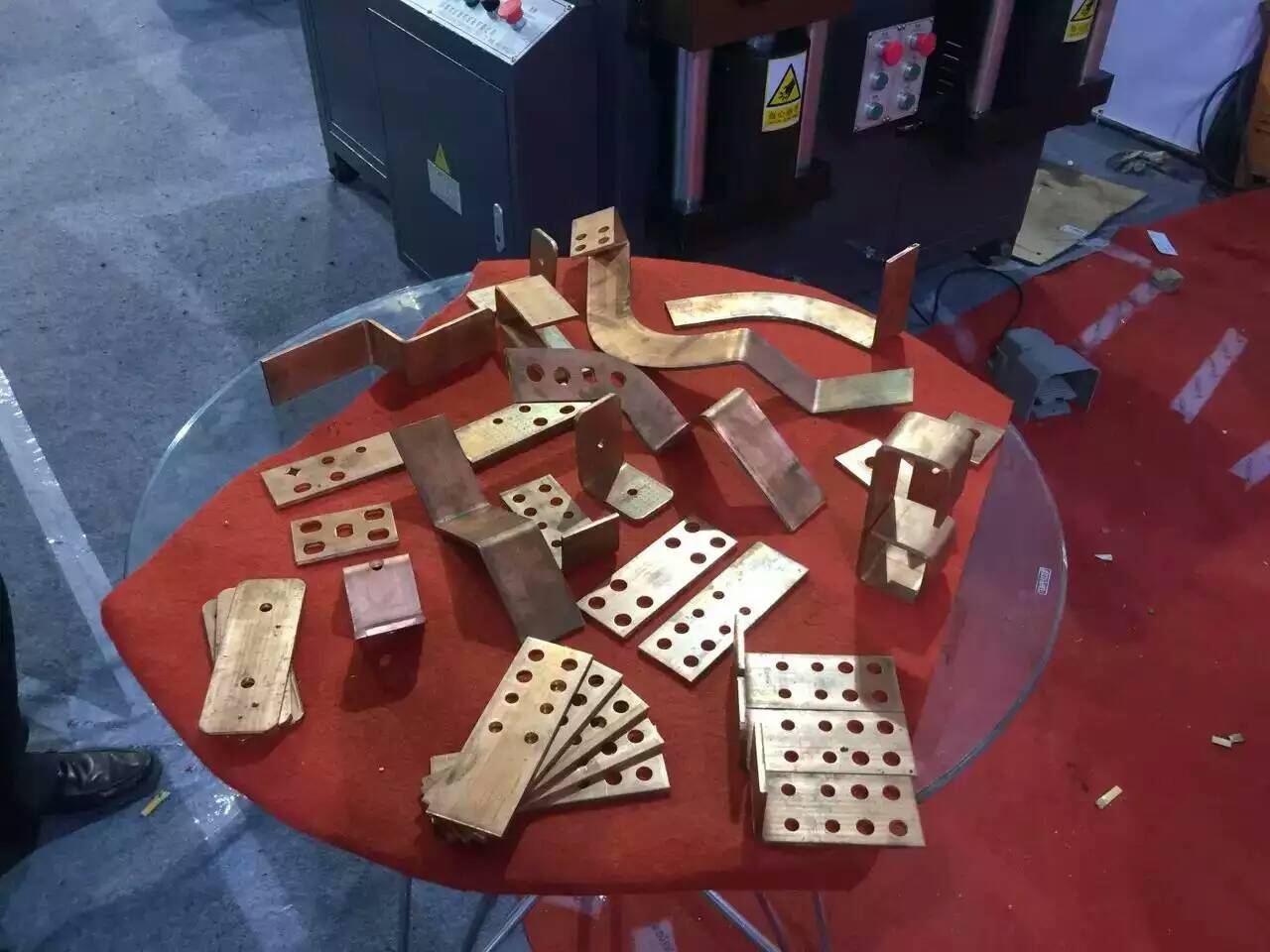

Processing Samples Display:

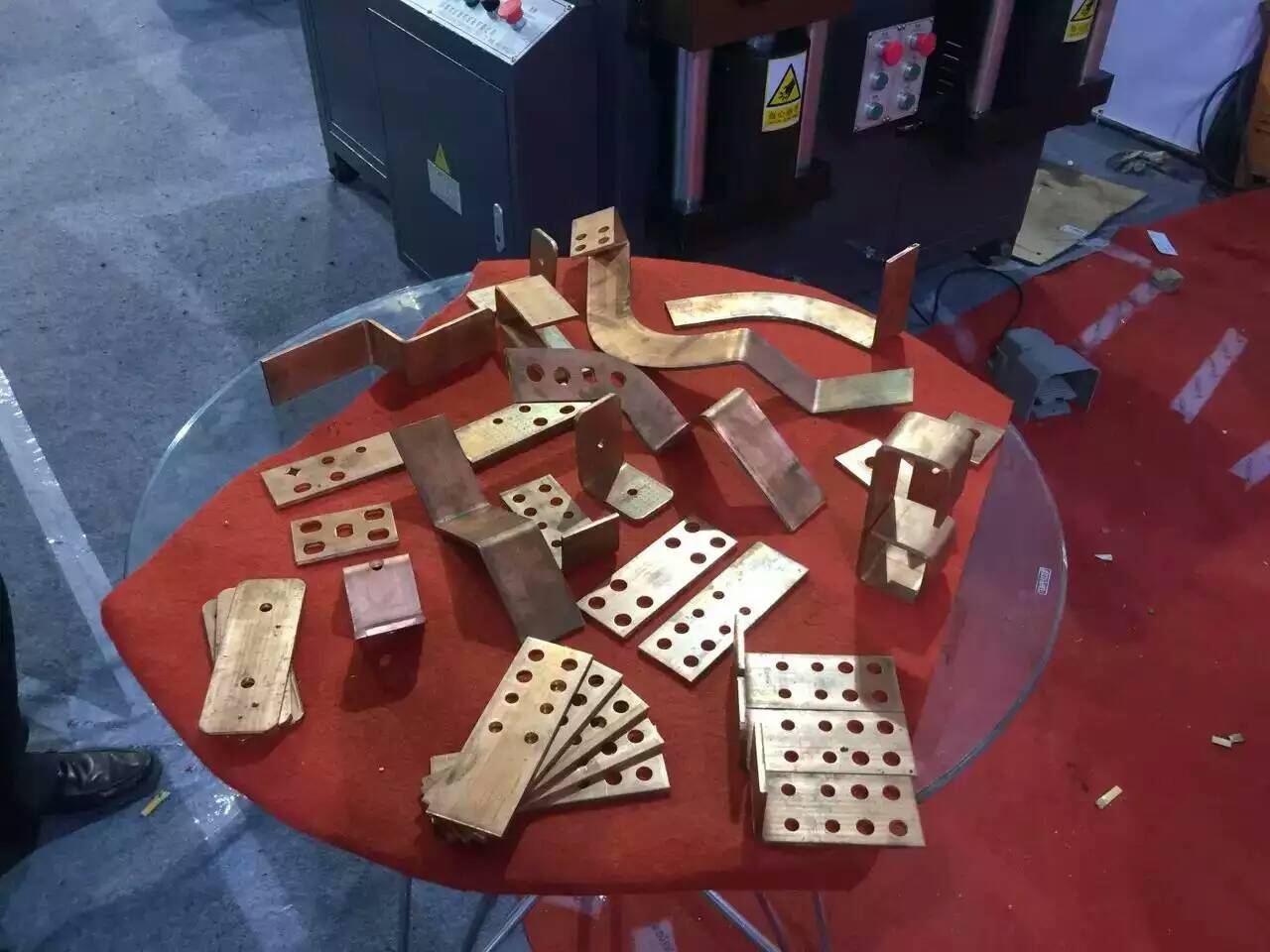

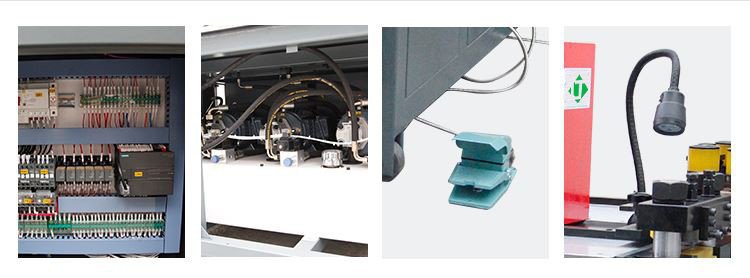

Machine Molds & Dies:

Looking for spare parts? We supply high-quality Hole Punching Molds, Cutting Blades, Bending Dies, and Customized Embossing Tools compatible with this machine.

LTMC Certifications:

Packaging and Shipping to India:

Double Table Busbar Machine Demo Video:

1. What is a "Double Decker" or Double Table Busbar Machine?

This is a heavy-duty CNC machine where the Punching/Cutting units and the Bending unit are placed on different levels (tables). This allows Simultaneous Operation of all three stations without interference, doubling production efficiency compared to single-table machines.

2. What operations can it perform?

It performs Shearing, Punching (Round/Oblong), Flat Bending, Vertical Bending, U-Bending, Embossing, Twisting, and Cable Connector pressing on Copper and Aluminium busbars.

3. What is the advantage of the Turret Punching Unit?

The 8-Mode Turret Turnplate eliminates the need to frequently change punching dies. You can keep 8 sets of dies installed, saving huge setup time and reducing labor intensity.

4. Does the Shearing unit waste material?

No. The shearing unit uses a sharp cutting method that ensures a smooth cut with no burrs, no droop, and zero waste.

5. Is the Bending Station easy to use?

Yes. The Bending station uses an Open Structure design, making it very easy to insert and remove long or heavy busbars.

6. Can I move the machine?

Yes, it is equipped with four heavy-duty casters for easy mobility within your workshop.

7. What are the operation modes?

It supports both Manual Button and Foot Switch operation, giving operators flexibility.

8. Can I get custom molds?

Yes. We can provide customized molds for Embossing, Twisting, or special bending shapes based on your drawings.

9. What industries is this machine suitable for?

It is perfect for Switchgear Panels (LT/HT), Power Distribution Centers, Transformer Manufacturing, and Busduct systems in India.

10. Is it suitable for mass production?

Absolutely. The Turret Punching + Double Table Simultaneous Operation design makes it the best choice for high-volume mass production.

11. What materials does it process?

It processes Copper (Cu) and Aluminium (Al) busbars of various standard sizes used in the Indian market.

Double Decker Busbar Machine Price India, CNC Double Table Busbar Processing Machine, Simultaneous Busbar Bending Punching Machine, Hydraulic Busbar Machine with Turret, Heavy Duty Copper Busbar Machine

Industry Keywords: Turret double table busbar machine, CNC busbar processing machine India, hydraulic busbar punching bending cutting machine, 3-in-1 busbar fabrication machine, copper aluminium busbar working machine, double decker busbar machine, turret busbar punching machine, double-table busbar processor, CNC copper busbar equipment, industrial busbar forming machine, high-efficiency busbar workstation, multi-function busbar processing equipment, electrical switchgear busbar machine, power distribution busbar fabrication equipment, busbar hole punching equipment, busbar cutting and bending tool, heavy-duty hydraulic busbar machine, copper patti machine, automatic busbar bending machine.