Looking for a heavy-duty Pneumatic Busbar Marking Machine? Our Integrated Dot Peen System delivers deep, permanent Pin Marking on Copper & Aluminium busbars. Ideal for Switchgear & Panel Builders requiring clear Phase & Neutral identification even after painting. Compatible with CNC Busbar Processing Lines. Contact us today for the best price in India and upgrade your busbar fabrication efficiency.

Best Quality 3-in-1 Copper/Aluminium Busbar Fabrication Machine (India Market)

Product Description:

This heavy-duty 3-in-1 Copper/Aluminium Busbar Fabrication Machine features three independent workstations: Punching, Shearing (Cutting), and Bending. Specifically designed for Indian Panel Builders and Switchgear Manufacturers, it allows simultaneous operation of all three units to reduce processing time and boost production efficiency for LT/HT panels.

Detailed Images & Features:

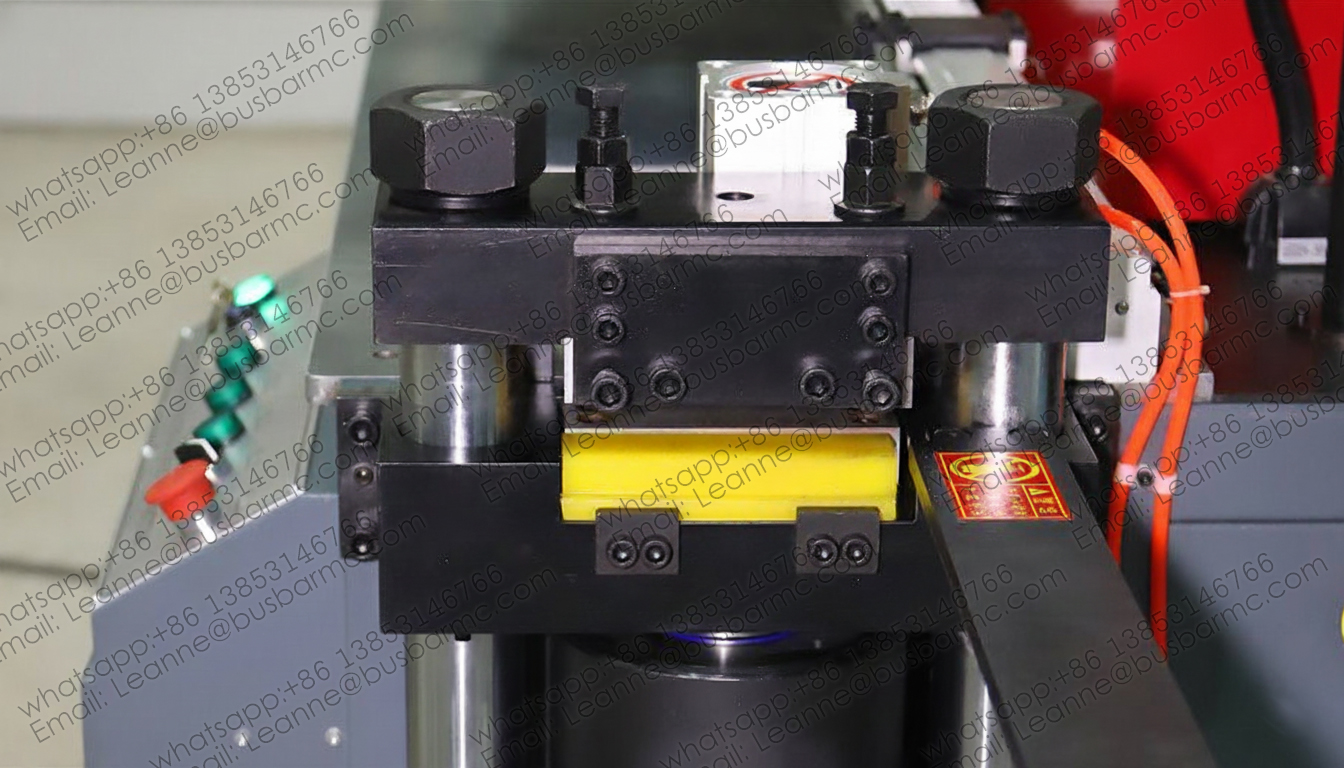

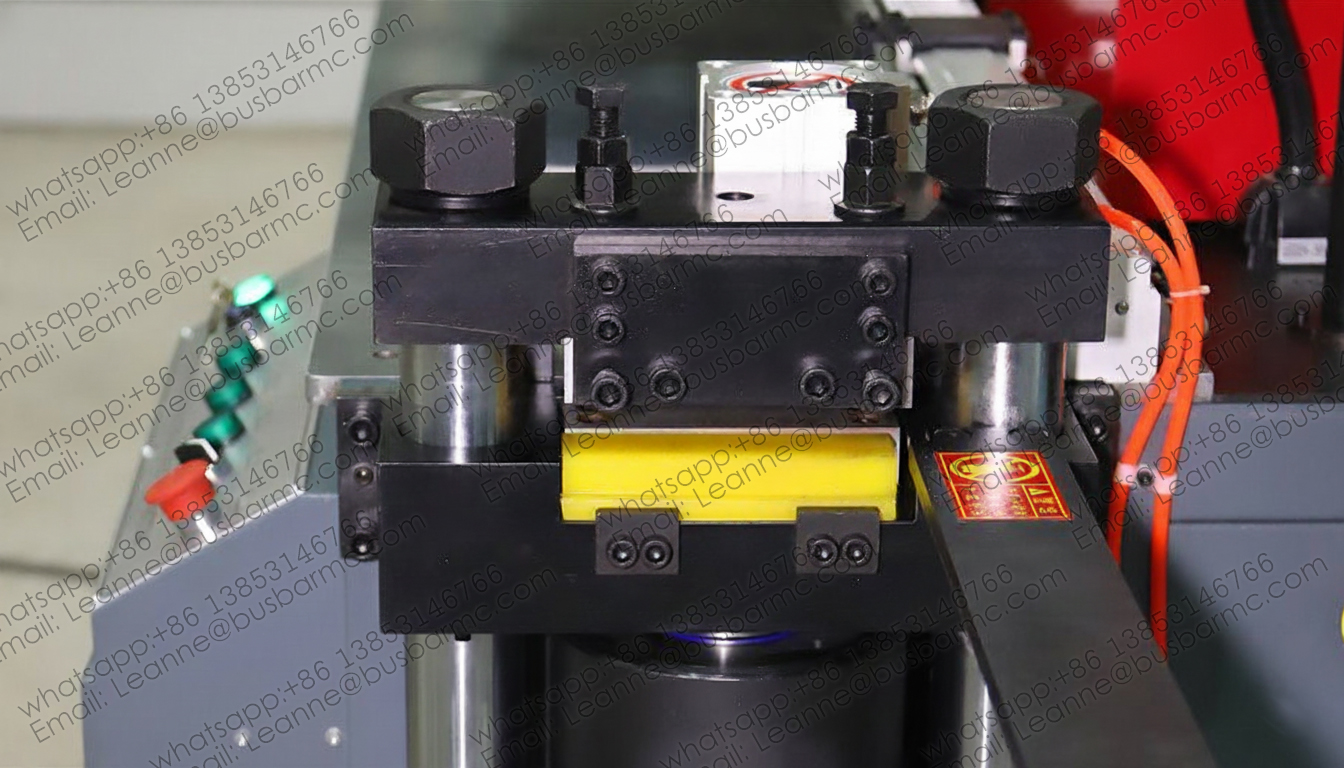

1. Cutting / Shearing Unit:

Uses a sharp shearing method (no scrap) to ensure a flat interface with no burrs or droops, saving expensive copper material.

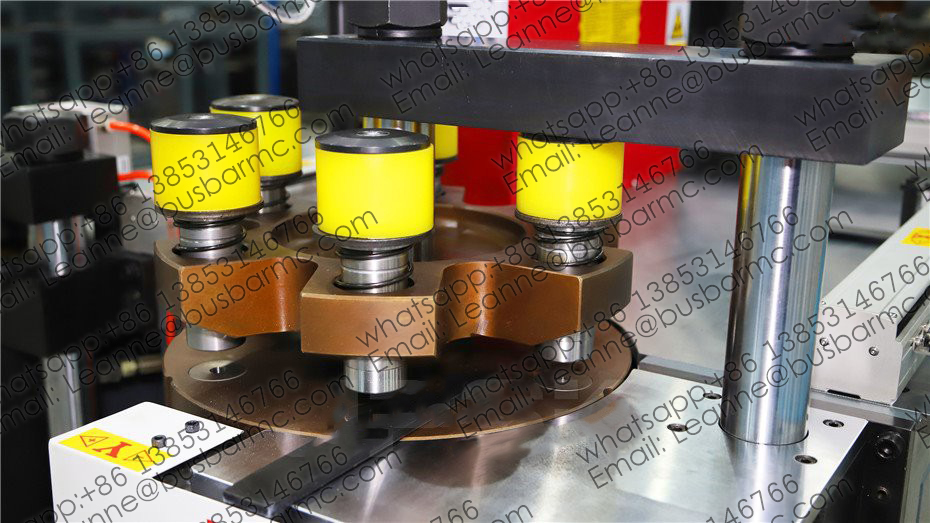

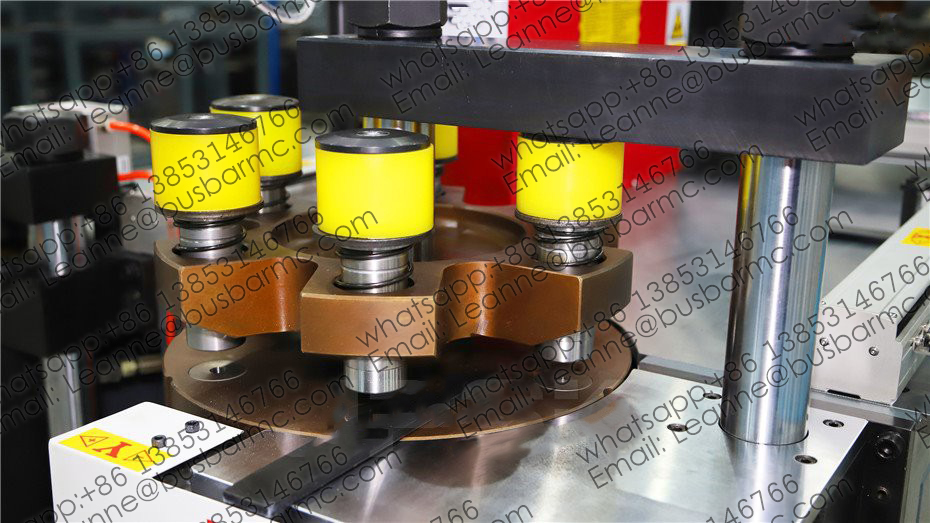

2. Punching Unit:

Equipped with a robust turntable (turret) structure, supports quick die changing for round, oval, and oblong holes.

3. Bending Unit:

Capable of performing Vertical (Flat) Bending, Horizontal Bending, U-Bending, and Embossing with high precision (PLC Control).

Detailed Technical Parameters:

|

Function |

Item |

Model: 303U-3-C |

|

Punching Unit |

Max. Punching Force (KN) |

300 |

|

Punching Diameter Range (MM) |

Ø4.3 - Ø25 |

|

|

Max. Thickness (MM) |

12 |

|

|

Max. Width (MM) |

160 |

|

|

Shearing / Cutting Unit |

Max. Shearing Thickness (MM) |

12 |

|

Max. Shearing Width (MM) |

160 |

|

|

Vertical Bending (Flat Bending) |

Max. Bending Force (KN) |

300 |

|

Max. Thickness (MM) |

12 |

|

|

Max. Width (MM) |

160 |

|

|

Horizontal Bending |

Max. Width (MM) |

100 |

|

Max. Angle (Degree) |

90° |

|

|

Out Dimension |

MM |

1800 * 1400 * 1480 |

|

Power |

KW |

3 * 4kw (Independent Hydraulic Motors) |

|

Weight |

KG |

1420kg |

|

CNC Precision |

Bending Precision |

±1° |

|

Repeat Bending Precision |

±0.3° |

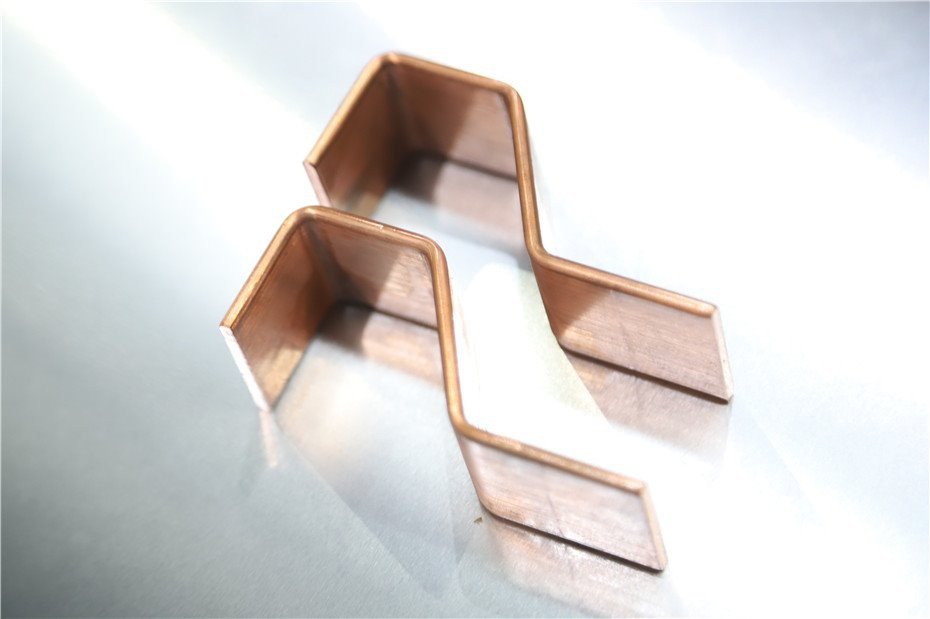

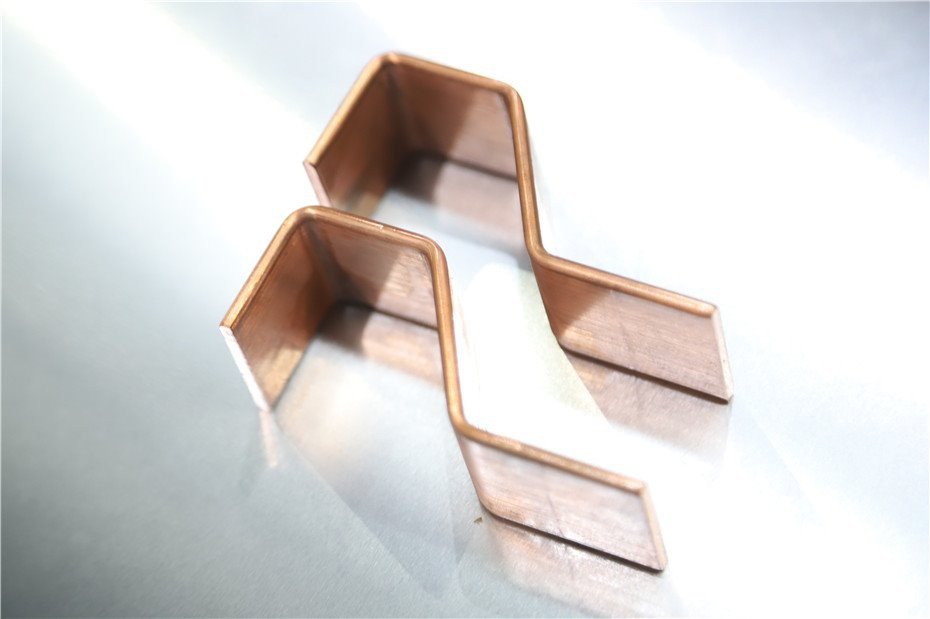

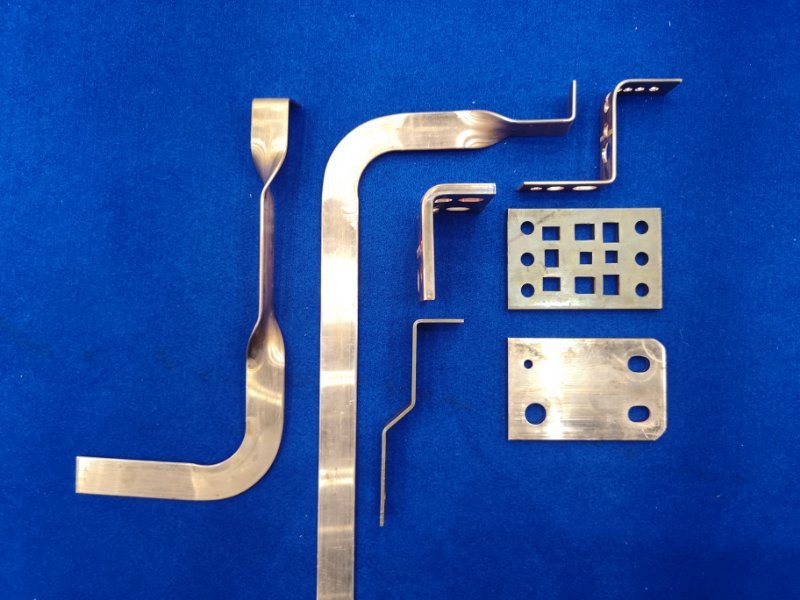

Processed Samples of Copper/Aluminium Busbar Fabrication Machine:

Factory & Workshop:

Hot Tags (India): 3 in 1 busbar machine price in India, copper busbar processing machine,

Hot Tags: 3 station busbar machine, hydraulic busbar bending machine, combined busbar machine, busbar cutting punching bending machine, busbar machine manufacturers in India, busbar bending machine price list, heavy duty busbar machine, copper busbar fabrication machine, aluminium busbar processing machine, switchgear manufacturing machines, busbar processing center, automatic busbar machine, busbar bending machine for LT panels, busbar bending machine HSN code, China supplier, factory price.

LT/HT Busbar Machine Demo Video:

1. What processes can this 3-in-1 busbar machine perform?

This versatile machine integrates three core functions: Punching, Shearing (Cutting), and Bending. Each unit has its own hydraulic cylinder and can operate independently and simultaneously.

2. Can it handle both Copper and Aluminium busbars?

Yes. It is designed to process both Copper and Aluminium busbars efficiently, suitable for standard Indian busbar sizes used in control panels.

3. What is the maximum Punching and Bending force?

The machine delivers a powerful 300KN force for both punching and vertical bending operations, ensuring clean holes and precise bends on thick busbars.

4. What is the range of hole sizes (Punching Diameter)?

The standard punching range is Ø4.3mm to Ø25mm. We also provide custom dies for oblong/oval holes required for switchgear assembly.

5. What is the maximum Busbar Size capacity?

It supports busbars up to 12mm in thickness and 160mm in width for Punching, Shearing, and Vertical Bending.

6. Does it support different Bending shapes?

Yes. It can perform Vertical Bending (Flat Bend), Horizontal Bending (up to 100mm width), U-Bending, and Embossing (with optional tools).

7. How accurate is the bending angle?

Thanks to the precision control system, it offers a bending accuracy of ±1° and a repeat bending precision of ±0.3°, meeting high-quality panel standards.

8. What is the power requirement?

The machine is equipped with three powerful 4kW motors (3 × 4kW), allowing heavy-duty continuous operation. We can customize the voltage (e.g., 415V, 50Hz) for the Indian power grid.

9. What are the machine dimensions and weight?

The compact design measures 1800mm × 1400mm × 1480mm and weighs approximately 1420kg, making it stable for factory floor installation.

10. How can I get the price in India?

Please contact our sales team directly for the latest 3 in 1 Busbar Machine Price in India including shipping and customs details.

3 in 1 Busbar Machine Price India, Hydraulic Busbar Cutter Puncher Bender, Copper Busbar Bending Machine for Panels, Aluminium Busbar Processing Machine, Busbar Fabrication Machine Manufacturer

Industry Keywords: 3 station busbar processing machine, combined busbar cutting punching bending machine, multipurpose busbar machine, busbar bending machine manual vs hydraulic, busbar machine for electrical panel board, busbar processing machine video, busbar bending calculation formula, busbar punching die size, heavy duty busbar bending machine, automatic busbar bending machine price, busbar machine spare parts, switchgear assembly tools, power distribution cabinet manufacturing machine, copper bar bending tool, hydraulic busbar press, busbar fabrication workshop equipment, busbar machine HSN code 8462, busbar bending machine Ahmedabad, busbar machine Mumbai, busbar machine Delhi.